Last updated on

Dive into this detailed examination of burnished slate metal roofs because their unique blend of durability and aesthetic appeal makes them an ideal alternative for contemporary roofing.

Key takeaways:

- Burnished slate metal roofs offer aesthetic appeal and durability.

- They are weather resistant and energy efficient.

- Installation process involves measurement, underlayment, panel laying, and more.

- Different profiles are available for different architectural styles.

- Burnished slate roofs are low maintenance and environmentally friendly.

Definition of Burnished Slate Metal Roof

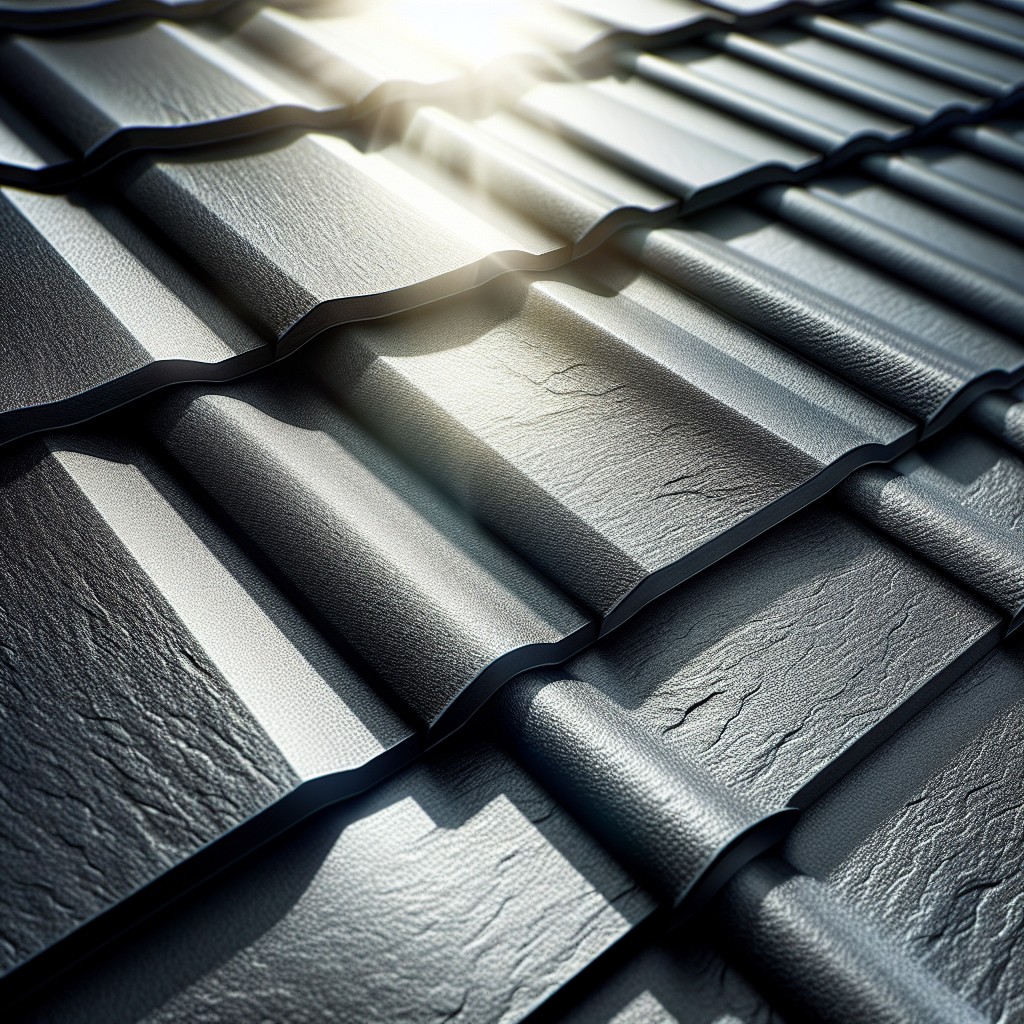

Burnished slate is a popular color finish for metal roofing systems that emulates the appearance of a sophisticated gray slate. It is characterized by its dark, muted tones that blend well with a variety of architectural styles, contributing to its increasing demand among homeowners.

This specialized pigment, coupled with a protective metallic coating, is applied to metal panels providing an elegant, yet durable roofing solution. Its unique aesthetic often features subtle variations, giving the appearance of natural weathering without the wear.

Properties of Burnished Slate Metal Roofing Material

Burnished slate metal roofing boasts a matte finish that mimics the aesthetic of traditional slate with a grayish-brown hue. This coating offers enhanced UV resistance, minimizing color fade over time.

The material typically comprises steel with a Zinc or Aluminum coating, providing resistance to corrosion. The gauge, or thickness, typically ranges from 22 to 29, with the lower numbers indicating greater durability.

This roofing material can endure extreme weather conditions, including high winds, hail, and heavy snow. The paint system used for the metal often includes a primer and a topcoat, which adheres well to the metal and contributes to the roof’s longevity.

The texture of the finished slate can vary, often depending on customer preference or specific product lines offered by manufacturers.

Advantages of Choosing a Burnished Slate Metal Roof

Opting for a burnished slate metal roof offers several compelling benefits:

1. Aesthetic Appeal: The distinctive, dark gray hue with slight variations mimics the look of traditional slate without the associated cost or weight.

2. Longevity: Metal roofs are renowned for their ability to withstand the elements, often lasting upwards of 50 years with proper maintenance.

3. Weather Resistance: This roofing material stands up to harsh weather, including heavy rain, hail, and strong winds.

4. Energy Efficiency: The reflective properties can help regulate indoor temperatures, potentially lowering cooling costs during warmer months.

5. Eco-Friendliness: Metal is a sustainable roofing choice, as it’s frequently made from recycled materials and is itself 100% recyclable at the end of its life cycle.

6. Installation: Offers the advantage of being lighter than traditional slate, making installation faster and reducing the load on your home’s structure.

By considering these advantages, homeowners can make an informed decision about their roofing needs while ensuring a harmonious blend of functionality and style.

Installation Process for Burnished Slate Metal Roofing

Installing a metal roof requires precision and attention to detail to ensure longevity and optimal performance. The burnished slate variety is no exception, offering a distinctive look alongside the renowned durability of metal roofs.

The process generally follows these steps:

- Roof Measurement and Inspection: Before panels arrive, a thorough measurement of the roof is needed to order materials. Also, an inspection checks for issues on the existing roof that need addressing.

- Underlayment Installation: A water-resistant layer is crucial. Synthetic underlayment is typically laid over the decking for added protection against moisture.

- Eave Flashing: This is the first metal piece installed at the edge of the roof to prevent water from seeping under the roof.

- Panel Laying: Beginning from the roof’s edge, metal panels are carefully aligned, ensuring each is square to the roof’s line. Sequential placement allows for overlapping, which diverts water away from seams.

- Securing Panels: Screws with rubber gaskets are used for securing panels to the roof. Correct screw placement through designated panel areas ensures a tight seal without compromising the metal’s integrity.

- Seam Connection: Some metal roofs have standing seams which are crimped together, further sealing the roof and providing a smooth aesthetic.

- Flashing Installation: Areas around vents, chimneys, and valleys where panels meet require metal flashing. This acts as an additional barrier against water penetration.

- Trim: To ensure a clean finish, trim is applied to the roof’s hips, ridges, and corners, complementing the burnished slate’s aesthetic and enhancing weather tightness.

It’s crucial to note that manufacturer instructions can vary. Therefore, following specific guidelines for the burnished slate material selected is vital for warranty validity and overall success.

Types of Burnished Slate Metal Roofing Profiles

Burnished slate metal roofing is available in multiple profiles to suit various architectural styles. The most common profiles include:

- Standing Seam: This profile features long, vertical panels that connect with raised interlocking seams. The concealed fasteners provide a sleek, modern appearance and enhance the roof’s waterproofing capabilities.

- Corrugated Panels: Known for their wavy design, these panels offer a traditional look and are often chosen for their strength and ability to handle water runoff effectively.

- Metal Shingles: Mimicking the appearance of standard shingles, this option delivers the aesthetic appeal of traditional roofing materials combined with the durability of metal.

- Metal Tile: These panels replicate the look of clay or concrete tiles and are a popular choice in regions where Mediterranean-style architecture is prevalent.

Each profile not only delivers a distinct aesthetic but also brings specific benefits in terms of performance, installation requirements, and ability to shed water or snow. Compatibility with local weather conditions and architectural design should guide the selection process.

Maintenance and Durability of Burnished Slate Roofs

Burnished slate metal roofs offer remarkable durability, often lasting 40-70 years with proper care. Their robust construction withstands severe weather, from driving rain to heavy snow, without corroding or cracking. The distinct slate-colored finish is also resistant to fading over time, ensuring a consistent aesthetic appeal.

For maintenance, these roofs require minimal effort. Routine checks should be carried out to ensure no debris has accumulated, potentially obstructing water flow. It’s also important to inspect for any signs of damage or loosening fasteners after extreme weather events. Should any sections sustain damage, they can be replaced individually, preventing the need for a full roof overhaul.

The innate strength of the metal combined with the protective coating on burnished slate ensures that issues like mold growth, insects, and fire threats are markedly reduced compared to other roofing materials. This inherent resilience not only provides peace of mind but can also translate to insurance savings due to the decreased risk of damage.

In summary, the maintenance regimen for these roofs involves occasional cleaning, periodic inspections, and swift repairs when necessary. Embracing these practices will secure their longevity and maintain the roof’s striking appearance for decades.

Energy Efficiency and Environmental Impact

Metal roofs, like those finished in burnished slate, contribute significantly to energy efficiency in several ways. Their reflective properties help deflect solar radiation, which means less heat is absorbed into the home, leading to potential savings on cooling costs during warmer months. Many burnished slate coatings are treated with special pigments that further enhance this reflectivity.

Additionally, these types of roofs are often eligible for Energy Star ratings, which can lead to tax credits for homeowners due to their environmentally friendly nature. In terms of environmental impact, metal roofing materials are highly sustainable. They are typically made with a percentage of recycled content and are themselves 100% recyclable at the end of their lifespan. This recyclability diminishes the need for new raw materials and reduces waste in landfills.

Furthermore, the durability of metal roofs means that they have a longer replacement cycle compared to traditional roofing materials. Longevity reduces the frequency of roofing material production, lowering the overall environmental footprint over time.

Lastly, the light weight of metal roofing puts less stress on home structures, potentially reducing resource use during initial construction or when retrofitting existing homes. This ease of handling and installation can also reduce emissions and energy consumption associated with transportation and labor.

Estimating the Cost of a Burnished Slate Metal Roof

The price of a burnished slate metal roof is influenced by several factors, with material costs and installation being primary components. Metal roofing panels typically range from $3.00 to $5.00 per square foot, but the premium finish and patterning of burnished slate can alter this base cost.

Roof size is the most significant determinant of the overall price. Larger roofs require more materials and labor, increasing the total cost. The complexity of the roof design also plays a role; intricate designs with multiple angles, peaks, and valleys are more labor-intensive and may necessitate additional materials such as flashing and fasteners.

Labor costs vary by region and are impacted by the skill level of the installation crew. A more experienced crew may command higher rates but might also provide superior workmanship and efficiency. Additionally, removing an old roof can add to labor costs and is often calculated by the square foot or hourly rate.

When considering insulation and underlayment, remember these materials are part of the roofing system but are quoted separately from the metal panels. These layers contribute to the roof’s energy efficiency and longevity, potentially saving money long term.

Lastly, the cost of delivery and freight for the roofing materials, which can fluctuate based on location and fuel prices, must be factored into the total estimate. Always request a detailed quote from roofing contractors to ensure clarity on the scope and cost of the project.

Complementary Trim and Flashing for Burnished Slate Roofs

Optimizing the aesthetic appeal and functional integrity of a burnished slate metal roof involves selecting appropriate trim and flashing. These elements serve both as a finishing touch and a means to prevent moisture penetration at the roof’s most vulnerable points, such as edges, valleys, and around penetrations like vents and chimneys.

Edge Trim: Provides a clean, defined line along the roof’s perimeter, enhancing its overall appearance and helping to channel water off the roof.

Ridge Cap: Fitted over the peak of the roof where two slopes meet; essential for keeping rainwater and debris out while maintaining a uniform look with the burnished slate color.

Valley Flashing: Installed in the roof valleys to efficiently direct water away from the roof and into the gutter system, made to match the burnished slate for a seamless integration.

Gable Flashing: Protects the roof’s edges from wind-driven rain and covers the terminating end of the horizontal panels, once again matching the hue for consistency.

Pipe Boots and Vent Flashing: Manufactured to fit around roofing protrusions, these elements are crucial for waterproofing vent pipes, exhaust flues, or chimney bases, and can be custom colored to fit the theme of the burnished slate material.

Ensuring that these accessories are correctly color-matched and installed is vital, as it impacts both the longevity of the roofing system and the visual harmony of the building’s exterior.

Ordering Information for Burnished Slate Metal Roofing Systems

Prior to placing an order for a burnished slate metal roof, essential preparation includes accurate measurements of the roof surface. This will ensure you order the correct amount of material. Choose a reputable manufacturer or supplier with a track record of quality products and customer service.

Consider the following when ordering:

- Gauge of Metal: Specify the thickness of the metal needed for your project, typically ranging from 22 to 29 gauge.

- Panel Profile: Decide on the style of panel; common profiles include standing seam, corrugated, and ribbed.

- System Components: Include necessary accessories such as fasteners, underlayment, trim, and flashing.

- Lead Time: Verify the supplier’s lead time to schedule your project accordingly.

- Warranty: Inquire about product warranties to protect your investment.

- Delivery: Arrange for transportation; some suppliers offer on-site delivery, but confirm if there are additional charges.

Always request a sample of the color and finish to ensure it matches your expectations. Engage with a sales representative to answer any technical questions and assist with your order, ensuring all requirements are met for a successful roofing project.

FAQ

What color is burnished slate metal roof?

A burnished slate metal roof is a lovely brown/gray finish that appears lighter in direct sunlight and softer/darker as evening arrives.

Does metal roof color matter?

Yes, metal roof color matters as light-colored roofs reflect sunlight, resulting in a cooler home in hot climates, and can provide energy savings between 25-40% depending on the specifics of the project.

Can a metal roof be installed over slate?

Yes, a metal roof can technically be installed over slate, however, it carries significant considerations and potential drawbacks.

Will galvalume rust if you cut it?

Yes, Galvalume can exhibit minor rusting at cut edges due to exposed steel, but its self-healing characteristics limit the extent, making it minimal and eventually stopping.

How does a burnished slate metal roof fare in different climates?

A burnished slate metal roof demonstrates high resilience irrespective of climate, enduring harsh weather conditions such as intense sunlight, snow, and heavy rains owing to its durability, energy-efficiency, and corrosion resistance.

Does the color of a metal roof affect its heat absorption?

Yes, the color of a metal roof significantly affects its heat absorption, with darker colors typically absorbing more heat than lighter ones.

What should be considered while installing a metal roof over existing slate material?

When installing a metal roof over existing slate material, it’s crucial to consider the structural capacity of the existing structure, underlayment applications, correct flashing installation, and the need for a ventilation system to prevent condensation-related issues.