Last updated on

This article provides detailed information about metal roof insulation, including its benefits, types, and installation process.

Key takeaways:

- Metal roof insulation maintains consistent indoor temperature.

- Insulation saves energy and reduces heating and cooling costs.

- Insulation prevents condensation, mold, and structural damage.

- Insulation dampens sound for a quieter indoor environment.

- Insulation extends the life of the roof and prevents stress.

Why Do We Need Metal Roof Insulation?

Insulation beneath a metal roof serves several key functions that directly impact both the efficiency and comfort of a building:

- Temperature Regulation: Insulation helps maintain a consistent indoor climate by reducing the heat exchange between the interior of a building and the outside environment.

- Energy Savings: By stabilizing indoor temperatures, insulation reduces the demand on heating and cooling systems, leading to considerable energy savings over time.

- Condensation Control: Insulation materials can help prevent condensation, which occurs when warm, moist air meets the cooler metal surface. If unaddressed, it can lead to corrosion, mold, and structural damage.

- Acoustic Performance: Metal roofs can sometimes amplify sound from rain, hail, or external noise. Insulation acts as a sound dampener, creating a quieter indoor environment.

- Enhanced Durability: Controlling temperature and moisture through proper insulation can extend the life of the roof and the structure as a whole by preventing thermal expansion and contraction, which can stress the metal and fasteners.

Each of these benefits plays a crucial role in maximizing the performance and longevity of a metal roofing system.

Metal Roof Insulation Options

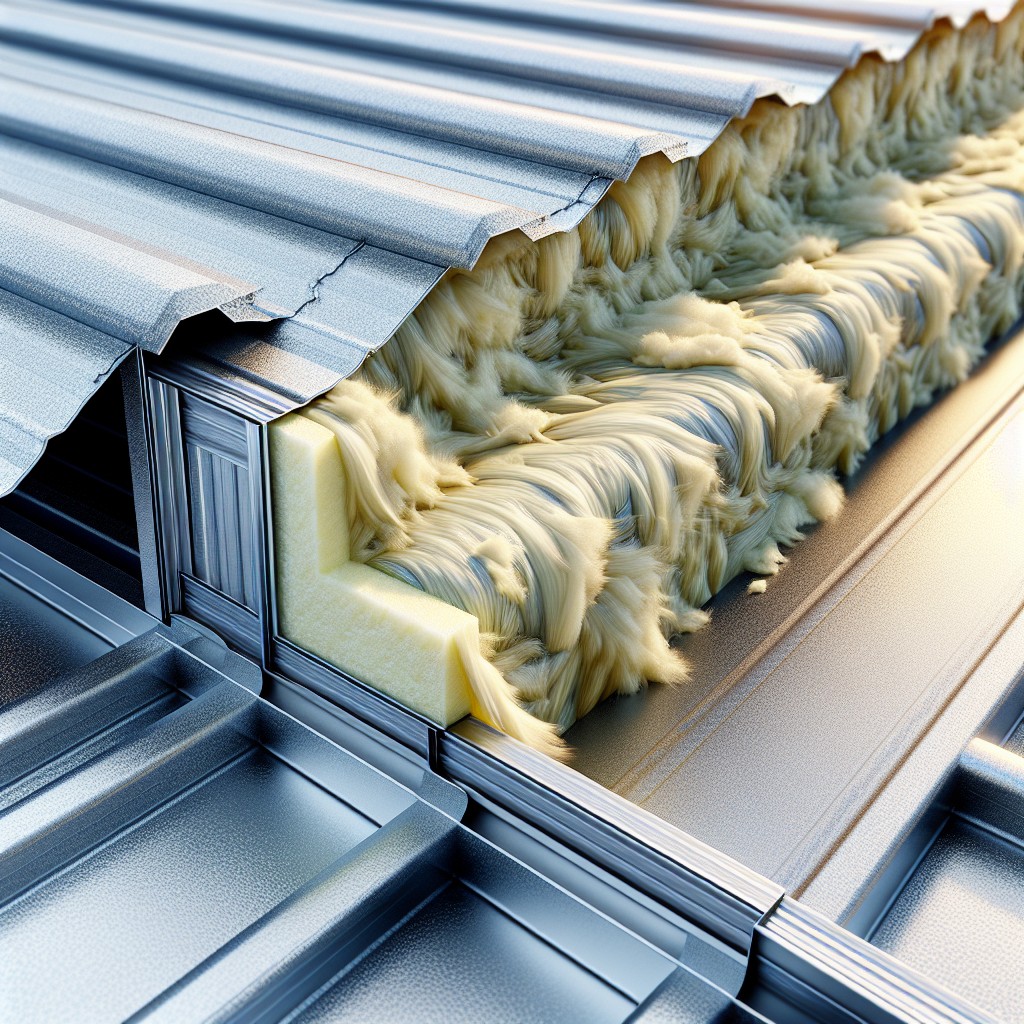

Several insulation options are suitable for metal roofs, each with distinct advantages and applications:

- Spray foam insulation provides an airtight seal and excellent R-values, enhancing thermal resistance and minimizing heat transfer.

- Rigid foam boards, like polystyrene or polyisocyanurate, offer high R-value per inch and can be applied directly to the metal roofing panels.

- Fiberglass batts are a cost-effective choice, easily fitted between roof purlins, but they require a vapor barrier to prevent moisture accumulation.

- Radiant barriers, typically thin layers of reflective foil, reduce heat gain from solar radiation, making them ideal in warmer climates for keeping buildings cooler.

- Mineral wool has superior fire resistance and soundproofing abilities, though it is denser and may require additional structural support.

Each of these options can be tailored to specific project needs, balancing cost, thermal performance, and ease of installation.

What to Consider Before Insulating a Metal Roof

When planning the insulation of a metal roof, several key factors must be evaluated to ensure optimal performance and longevity:

- Climate: The local weather conditions dictate the R-value required to maintain energy efficiency. In colder regions, higher R-values are necessary to retain heat, while in warmer climates, the focus may be on reflecting heat away.

- Roof Design: The architectural design, including the slope and shape of the roof, will influence insulation choices. For flat or low-slope roofs, a more robust waterproofing strategy is often required.

- Existing Roof Condition: Assess the current state of the roof to determine if repairs or a complete overhaul are needed before insulation can be added.

- Ventilation: Proper ventilation is crucial in avoiding condensation, which can lead to rust and reduced insulation effectiveness. Ensure that the insulation strategy allows for adequate airflow.

- Moisture Control: Include a vapor barrier to prevent moisture from seeping into the insulation, as trapped moisture can degrade insulation materials and lead to mold growth.

- Material Compatibility: Verify that the insulation material is compatible with metal roofing to prevent chemical reactions that could lead to corrosion.

- Installation Process: Decide whether to install insulation during a new roof installation or retrofit it onto an existing structure, as this will affect the choice of materials and methods.

- Building Codes and Standards: Adhere to local building codes for insulation, which may specify requirements for fire resistance, thermal performance, and materials used.

By carefully considering these factors, you’ll be well-equipped to choose the right insulation solution for your metal roof.

How to Insulate a Metal Roof

Insulating a metal roof involves several steps to enhance energy efficiency and mitigate issues such as condensation and thermal bridging. Here are key points in the installation process:

1. Choose the right insulation material based on R-value requirements, local climate, and budget considerations. Options typically include rigid foam, spray foam, fiberglass, or reflective insulation.

2. Install a vapor barrier when necessary to prevent moisture from passing through the insulation, which is crucial in climates with high humidity or when the indoor space is temperature-controlled.

3. Secure thermal spacers between the metal roofing and the insulation material to create a thermal break, reducing heat transfer and potential for condensation on the underside of the metal roof.

4. Apply the insulation uniformly across the roof, ensuring that it is snugly fitted to prevent gaps where heat or cold can infiltrate.

5. For existing roofs, consider utilizing a spray foam application that adheres to the interior side of the metal roof, providing insulation and sealing air leaks simultaneously.

6. Always follow local building codes and manufacturer guidelines to ensure the insulation’s performance and longevity are maximized, and that the roof’s structural integrity is maintained.

7. Engage a professional when necessary, especially when dealing with complex roof designs or when high-performance insulation systems are required.

Taking the time to properly insulate a metal roof pays dividends in comfort, energy savings, and roof longevity.

FAQ

What is the best way to insulate a metal roof?

The most effective method to insulate a metal roof is by utilizing spray foam due to its durable, long-lasting properties, and its capability to reduce air leakages, thereby air sealing your home.

Should insulation touch metal roof?

Yes, insulation should touch a metal roof as it is commonly practiced for fiberglass insulation to directly interact with the steel panels in building construction.

What is the best insulation for a metal shed roof?

The best insulation for a metal shed roof is reflective foil due to its ease of installation, cost-effectiveness, and rust resistance.

What is the best thing to put under a metal roof?

The best thing to put under a metal roof is felt underlayment, also known as asphalt felt or tar paper.

How does radiant barrier insulation work on metal roofs?

Radiant barrier insulation works on metal roofs by reflecting radiant heat, reducing the heat transfer from the roof to the interior of the building, thus lowering cooling costs.

What are the potential issues with metal roof insulation?

Potential issues with metal roof insulation can include moisture condensation, thermal bridging, corrosion, and difficulties during installation.

How does insulation improve the energy efficiency of a metal roof?

Insulation improves the energy efficiency of a metal roof by reducing heat transfer, thus lessening the need for artificial heating or cooling.