Last updated on

Exploring mill finish metal roofs becomes fascinating because of their unique attributes that offer durability, low maintenance, and an industrial yet chic aesthetic appeal.

Key takeaways:

- Mill finish metal roofs offer durability and low maintenance.

- They are cost-effective and energy-efficient.

- Installation is easy, and the roofs are environmentally friendly.

- The roofs are durable and long-lasting.

- Consider aesthetics, misconceptions, and choosing the right contractor.

Definition of Mill Finish Metal Roof

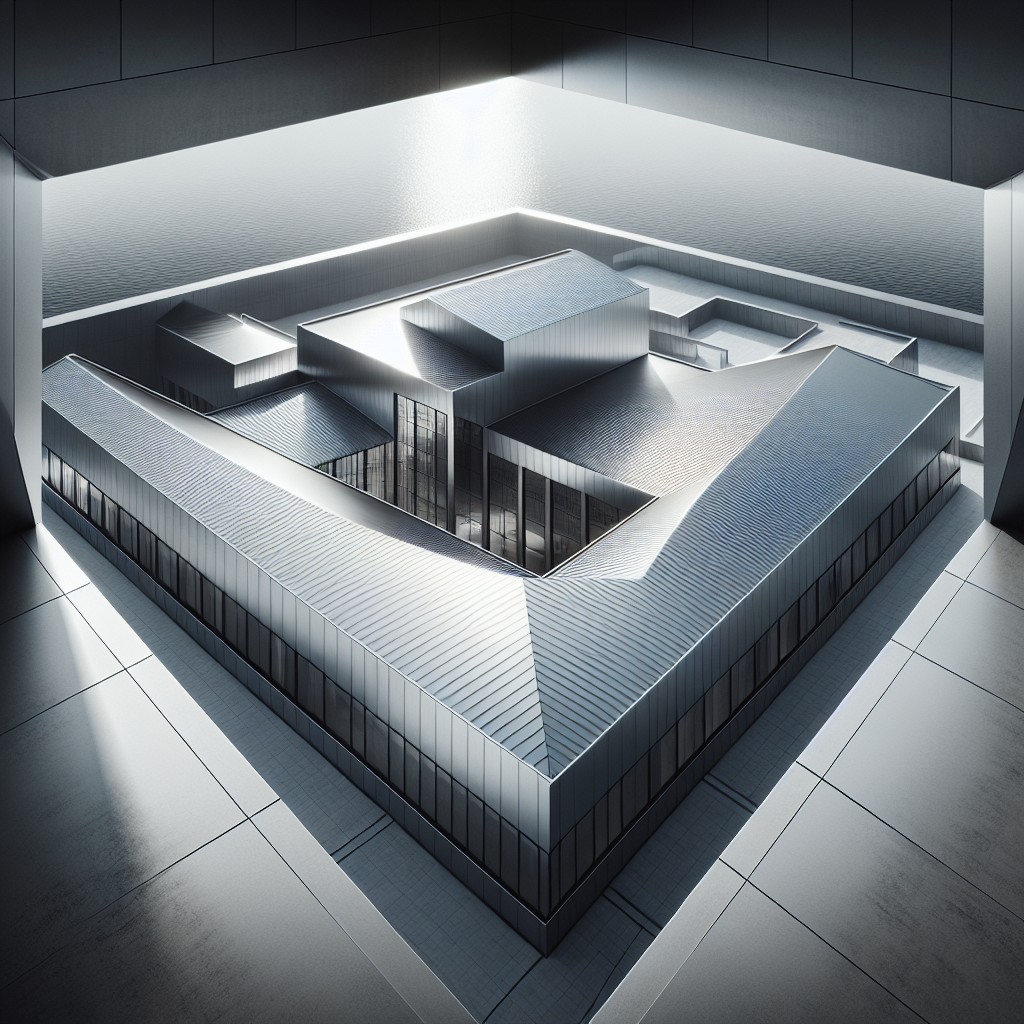

A mill finish metal roof is characterized by its raw, unpolished appearance directly from the rolling mill. The absence of additional surface treatments or coatings allows the natural texture and color of the metal, such as aluminum or steel, to stand out. This can result in variations in the surface, reflecting the authenticity of the material.

The term ‘mill finish‘ is often associated with a more industrial look and is appreciated for its simplicity and minimalistic appeal. It’s important to note that this finish may evolve over time as the metal is exposed to weather, developing a unique patina that can add character to a building’s exterior.

Benefits of Mill Finish Metal Roofing

Mill finish metal roofs offer a host of advantages that can appeal to both commercial and residential property owners. They are known for their sleek, natural appearance which can complement various architectural styles. Thanks to the absence of coatings or finishes, these roofs showcase the bare metal in its original state, which can lead to a uniform patina as it ages, especially in materials like copper or zinc.

In terms of practicality, mill finish metal is often more affordable upfront compared to prefinished options. This cost-effectiveness doesn’t sacrifice performance; these roofs are still highly resistant to fire, pests, and rot, ensuring a layer of protection for the structure beneath.

The reflective properties of mill finish metal also contribute to energy efficiency. By reflecting sunlight rather than absorbing it, these roofs can reduce cooling costs during hotter months. In cooler climates, proper insulation in conjunction with a mill finish roof creates an effective thermal barrier.

Another benefit is the ease of installation. The absence of a finish means there’s no need to manage the complexities of matching colors or dealing with the potential chipping or scratching of a prefinished surface during installation.

Last but not least, for those concerned about the environment, mill finish metal roofing is typically made from recycled materials and is itself fully recyclable at the end of its lifespan, promoting a sustainable building practice.

Maintenance Requirements for Mill Finish Metal Roofs

Mill finish metal roofs boast a natural appearance and a protective oxide layer, which typically necessitates minimal upkeep. Regular maintenance includes:

- Inspection: Perform biannual inspections to check for any damage or debris accumulation.

- Cleaning: Gently remove leaves, branches, and other debris using a soft brush to prevent scratches on the surface.

- Gutter Care: Clean gutters and downspouts to ensure proper drainage and prevent water pooling. Clogged gutters can lead to water backing up and potentially damaging the roof structure.

- Scratch and Dent Care: While mill finish metals are resilient, any visible scratches or dents should be assessed by a professional to avoid rust or structural issues.

- Chemical Exposure: Limit the roof’s exposure to harsh chemicals or salts, which can corrode the metal over time. If such contact occurs, rinse the area with water.

By adhering to these simple practices, mill finish metal roofs will maintain their functional integrity and aesthetic appeal over time.

Durability and Longevity of Mill Finish Metal Roofs

Mill finish metal roofs boast impressive resilience against environmental factors. The natural surface, unmarred by paint or additional coatings, inherently resists the corrosive effects of rain, snow, and UV radiation. This innate strength significantly contributes to the material’s longevity, with life expectancies often exceeding 50 years.

Furthermore, these roofs exhibit commendable sturdiness in the face of physical stress. They can withstand high winds, hail, and other impacts without compromising their structural integrity. Their ability to expand and contract with temperature fluctuations without sustaining damage ensures consistent performance through the seasons.

Additionally, metal’s fire-resistant properties add an extra layer of security, potentially reducing the risk of devastation in the event of a fire. The absence of a finish means there is no need for recoating over time, simplifying long-term maintenance while preserving roof health.

Overall, the endurance of mill finish metal adequately supports its reputation as a set-it-and-forget-it roofing solution, catering to those prioritizing both robustness and a maintenance-minimal lifestyle.

Installation Process for Mill Finish Metal Roofs

Installing a mill finish metal roof requires precision and expertise to ensure longevity and performance. The process typically involves the following steps:

- Surface Preparation: The roof decking must be clean, dry, and free from any debris or irregularities that could affect the metal panels’ placement.

- Safety Measures: Installers should use appropriate safety equipment such as harnesses and guardrails, especially when working on steep slopes or at significant heights.

- Underlayment Installation: A high-quality underlayment is laid down to provide an additional barrier against moisture and to improve overall roof durability.

- Panel Cutting and Shaping: Metal panels, usually made from aluminum or steel, are cut to the specific dimensions of the roof and shaped if necessary, often at the job site to minimize transportation damage.

- Securing Panels: Panels are attached to the roof’s structure using clips or fasteners, allowing for thermal expansion and contraction.

- Sealing Joints: Sealants are applied to overlaps and joints to prevent water ingress.

- Trim and Flashing: Metal trim and flashing are installed at the edges, around the chimney, vents, and where the roof meets a vertical wall to prevent water penetration.

- Final Inspection: A thorough inspection ensures all components are correctly installed and that there are no issues that could lead to future problems.

Proper installation is crucial for mill finish metal roofs to perform effectively, hence the importance of hiring skilled professionals with experience in metal roofing installation.

Environmental Impact of Mill Finish Metal Roofs

Mill finish metal roofs contribute positively to environmental sustainability in several ways. Firstly, they are often made from recyclable materials and are themselves 100% recyclable at the end of their life span, reducing landfill waste. The reflective properties of the bare metal also mitigate the urban heat island effect by reflecting solar radiation, which, in turn, can lower cooling costs and energy consumption in buildings.

Additionally, the production process of mill finish metal typically involves fewer chemicals and pollutants compared to coated metal roofs, resulting in a lower environmental footprint during manufacturing. Furthermore, the durability and low maintenance needs of these roofs mean less frequent replacements and repairs, conserving resources over time.

Cost Comparison of Mill Finish Vs. Coated Metal Roofs

When considering a metal roof, budget often plays a significant role. In initial costs, mill finish options tend to be less expensive than their coated counterparts due to the absence of additional finishing processes. Coatings can drive up the price not only because of the materials used but also due to the labor and time involved in the application.

Cost savings with mill finish metal roofing can be significant, but it’s essential to balance the upfront costs with potential long-term benefits. A coated metal roof may offer more extended warranties, reflectivity that reduces cooling costs, and greater resistance to the elements. These factors, in the long run, could offset the initial investment.

On the other hand, the raw appearance of the mill finish can be desirable for certain architectural styles and could potentially lead to cost savings on painting or refinishing over the roof’s life span.

In sum, the choice between mill finish and coated metal roofing should be weighed carefully, considering both immediate budget constraints and future financial implications.

Aesthetic Considerations for Mill Finish Roofs

Mill finish metal roofs offer a natural, industrial appearance that can be both modern and timeless. Their sleek, uncoated surface reflects a minimalist aesthetic which may develop a unique patina as it ages, adding character to the building. This can be particularly appealing for architectural designs that aim to showcase raw materials and clean lines.

When selecting a mill finish for your roof, consider the surrounding environment. The material will interact with local elements, resulting in color changes and varying textures over time. In coastal areas, for example, a saline atmosphere may accelerate patination. However, in urban or industrial settings, external factors may contribute to a more uniform aging process.

Lighting plays a significant role in the perception of a mill finish roof. The angle of sunlight can alter the appearance throughout the day, giving the surface a dynamic quality. Strategically placed artificial lighting can also enhance the roof’s visual appeal at night.

The color and style of neighboring structures should also be factored into your decision. A mill finish roof can complement a wide range of palettes and designs, but it’s essential to consider how it will fit into the existing architectural landscape to achieve a coherent look.

Common Misconceptions About Mill Finish Metal Roofs

Mill finish metal roofs are often associated with various myths that can lead to confusion for homeowners and contractors alike.

Prone to Rust: A common belief is that these roofs are highly susceptible to rust. However, the natural patina that forms on metals like aluminum and copper actually serves as a protective layer, enhancing the roof’s resistance to corrosion.

Lack of Color Options: Some think that mill finish means a lack of color options. In reality, mill finish refers to the surface texture and not the color; these roofs can be painted or treated for color if desired.

Unsuitable for Residential Use: There’s a misconception that mill-finish is exclusively for industrial applications. Today’s designs blend seamlessly with both modern and traditional residential styles, proving this assumption incorrect.

Higher Maintenance Needs: The idea that they require constant upkeep is unfounded. Mill finish metal roofs demand minimal maintenance, with occasional cleaning and inspections being sufficient.

No Energy Benefits: The myth that these roofs offer no energy efficiency is inaccurate. They reflect sunlight and can help keep buildings cooler, contributing to reduced energy costs.

Understanding these points helps in making an informed decision about whether mill finish metal roofing is the right choice for a project. It’s essential to distinguish fact from fiction to appreciate the true value and potential of these roofing systems.

How to Choose the Right Contractor for a Mill Finish Metal Roof Installation

Selecting a capable contractor is pivotal for ensuring the successful installation of your mill finish metal roof. Start by verifying the contractor’s license and insurance to protect against potential liability. Look for a proven track record, requesting and following up on references to confirm the quality of previous installations. Prioritize those with specific experience in mill finish metal applications, as they will be familiar with the nuances of installing roofs without protective coatings.

Inquire about the contractor’s understanding of local building codes and weather considerations, as these will influence the installation process and materials used. Insist on a detailed proposal that outlines the scope of work, materials, timelines, and costs. Communication is key; ensure the contractor is willing to address your questions and concerns throughout the project.

Lastly, review warranties and post-installation support. A reputable contractor will offer warranties both on their craftsmanship and the roofing materials, and they should be willing and able to provide maintenance services or advice for the life of your roof.

FAQ

What is a mill finish on a metal roof?

A mill finish on a metal roof refers to the raw, uncoated state of the metal, which with extended exposure to environmental elements, will naturally acquire a patina.

What is the best finish for a metal roof?

The best finish for a metal roof is the polyvinylidenefluoride (PVDF) finishes, known for their superior fade and chalk resistance, and commonly sold under the brand names of Kynar™ and Hylar™.

Is matte or shiny metal roof better?

The choice between a matte or shiny metal roof is subjective, depending on factors such as aesthetic preference and durability, with matte finishes often chosen for their aesthetic appeal, and shiny finishes for their higher durability and dramatic appeal.

What is the toughest metal roofing?

The toughest metal roofing material is copper due to its longevity and premium quality.

How does a mill finish impact the longevity of a metal roof?

A mill finish, which leaves a metal roof bare and untreated, can reduce its longevity due to increased vulnerability to elements such as weathering, corrosion, and UV rays.

What are the benefits of a matte finish versus a gloss finish on a metal roof?

Matte finishes on metal roofs reduce glare, resist marring and scratching, hide imperfections, and attract less dirt compared to gloss finishes, which, although adding visual appeal and reflecting sunlight, show up imperfections, attract more dust, and are more susceptible to scratches.

Can a mill finish help increase the corrosion resistance of metal roofs?

Yes, a mill finish can enhance the corrosion resistance of metal roofs as it provides a natural surface with no additional coatings.