Last updated on

Explore the various types of roof sheathing as we dive into their unique characteristics, benefits, and applications in today’s roofing industry.

Roof sheathing is an essential component of any roofing system. It serves as the foundation for the roofing material, providing a flat and stable surface for installation.

Roof sheathing also plays a crucial role in protecting your home from weather elements such as rain, snow, and wind. With so many different types of roof sheathing available in the market today, it can be challenging to determine which one is right for your home.

In this article, we will take a closer look at some of the most popular types of roof sheathing and their unique features to help you make an informed decision when choosing the best option for your roofing needs. So let’s dive in!

Plywood Sheathing

Plywood sheathing is one of the most commonly used types of roof sheathing in residential and commercial construction. It is made from thin layers or plies of wood veneer that are glued together to form a strong and durable panel.

Plywood comes in various thicknesses, ranging from 3/8 inch to 1 inch, with thicker panels providing greater strength and stability.

One significant advantage of plywood sheathing is its ability to resist moisture damage better than other types of roof decking materials. This makes it an ideal choice for areas with high humidity levels or frequent rainfall.

Another benefit is its ease-of-use during installation as it can be cut easily into any shape required for the roofing project without compromising on structural integrity.

However, plywood’s main disadvantage lies in its cost compared to other options such as OSB (oriented strand board) which has become increasingly popular due to being more affordable while still offering similar durability characteristics.

Oriented Strand Board (OSB) Sheathing

It is made by compressing and gluing together strands of wood in a specific orientation to create a strong, durable panel. OSB sheathing comes with several benefits, including its affordability and ease of installation.

One significant advantage of OSB sheathing over traditional plywood is its resistance to moisture damage. Unlike plywood, which can delaminate when exposed to water for extended periods, OSB maintains its structural integrity even when wet.

Another benefit of using OSB as your roof decking material is that it’s more environmentally friendly than other options like plywood or fiberboard because it uses smaller trees or wood chips instead.

However, there are some downsides to consider before choosing this option for your roofing project. One disadvantage could be the fact that the edges tend not to hold up well under heavy loads compared with those on CDX Plywood panels.

Fiberboard Sheathing

It is an eco-friendly option that provides excellent insulation and soundproofing properties. Fiberboard sheathing comes in various thicknesses, ranging from 1/2 inch to 1 inch, making it suitable for different roofing applications.

One of the significant benefits of fiberboard sheathing is its ability to resist moisture and mold growth. This feature makes it ideal for use in areas with high humidity levels or where there are frequent rainfalls.

Another advantage of fiberboard sheathing is its ease of installation. It can be easily cut using standard tools such as saws or knives, making the installation process quick and straightforward.

However, one downside to consider when choosing fiberboard as your roof decking material is that it may not be strong enough to support heavy loads like other types such as plywood or OSB board. Therefore, if you plan on installing heavier roofing materials like tiles or slate shingles on top of your roof deckings, you might want to consider other options instead.

Radiant Barrier Sheathing

It is made up of an aluminum foil layer laminated to the underside of the roof decking, which reflects heat away from your home during hot summer months and helps retain warmth inside during colder seasons. This reflective barrier can reduce attic temperatures by up to 30 degrees Fahrenheit, making it easier for your air conditioning system to cool down your home and reducing energy costs.

Radiant barrier sheathing also provides excellent moisture resistance properties that help prevent mold growth and rotting in the roofing structure. Its durability ensures long-lasting protection against harsh weather conditions such as wind-driven rain or snow.

While radiant barrier sheathing may come at a higher cost than traditional plywood or OSB options, its energy-saving benefits make it worth considering for homeowners looking for ways to reduce their carbon footprint while saving money on utility bills over time.

Structural Insulated Panels (SIPs)

SIPs consist of two outer layers of oriented strand board (OSB) or plywood, with an insulating foam core in between. This design provides excellent thermal insulation, making it easier to maintain a comfortable temperature inside your home while reducing energy costs.

In addition to their insulation properties, SIPs also offer superior structural support compared to traditional roof sheathing materials like plywood or OSB. They can withstand high winds and heavy snow loads without warping or cracking.

One downside of using SIPs is that they can be more expensive than other types of roof sheathing materials. However, the long-term savings on energy bills may offset this initial cost.

Diagonal Tongue-and-Groove Sheathing

This type of sheathing is made from solid wood planks that are installed diagonally across the rafters, creating a strong and stable base for the roofing material. The diagonal installation pattern provides additional strength to the roof structure, making it more resistant to wind uplift and other weather-related damage.

One advantage of using diagonal tongue-and-groove sheathing is its aesthetic appeal. The natural beauty of wood adds warmth and character to any home’s exterior while providing excellent insulation properties.

However, one disadvantage with this type of roof decking is its cost compared to other types such as OSB or plywood. It also requires skilled labor during installation due to its unique design which can add up on labor costs.

Despite these drawbacks, many homeowners still prefer diagonal tongue-and-groove sheathing because it offers superior durability over time when properly maintained.

Zip System Roof Sheathing

It is an all-in-one structural panel with built-in moisture and air barriers, making it an excellent choice for homeowners who want to ensure their roofs are well-protected from the elements. The Zip System Roof Sheathing comes with a unique tongue-and-groove design that allows for easy installation and eliminates the need for additional sealing tapes or house wraps.

One of the benefits of using Zip System Roof Sheathing is its ability to provide superior protection against water intrusion. Its advanced technology ensures that your roof remains dry even during heavy rainstorms, reducing the risk of mold growth and other water-related damages.

Another advantage of this type of sheathing is its energy efficiency properties. The built-in air barrier helps reduce heat loss through your attic space, resulting in lower energy bills throughout the year.

Waferboard Sheathing

It is made by compressing wood strands and resin under high pressure to create a strong and durable panel. Waferboard sheathing comes in various thicknesses, ranging from 7/16 inch to 1 inch.

One of the benefits of waferboard sheathing is its affordability compared to other types of roof decking materials such as plywood or fiberboard. It has excellent dimensional stability due to its manufacturing process which involves aligning the strands for maximum strength.

However, one downside with waferboard sheathing is that it can be prone to swelling when exposed to moisture over time if not properly sealed or installed with adequate ventilation underneath the roofing material. This can lead to warping and buckling which may compromise your roofing system’s integrity.

Metal Sheathing

It is made from various metals such as aluminum, copper, zinc, or steel. Metal sheathing can be installed in different forms such as standing seam panels or corrugated sheets.

One of the significant benefits of metal sheathing is its resistance to weather elements like rain and snow. It also has excellent fire-resistant properties that make it an ideal option for areas prone to wildfires.

Another advantage of metal sheathing is that it requires minimal maintenance compared to other types of roof sheathings. However, proper installation by a professional roofer ensures optimal performance and lifespan.

While metal roofs may have higher upfront costs than some other materials like asphalt shingles or plywood decking, they are often more cost-effective over time due to their long lifespan and low maintenance requirements.

Gypsum Board Sheathing

It is made of gypsum plaster and paper, which are sandwiched together to create a strong and durable material. Gypsum board sheathing can be used in both residential and commercial roofing applications.

One of the benefits of using gypsum board as roof sheathing is that it provides excellent fire resistance. In fact, many building codes require the use of fire-rated materials in certain areas, such as near chimneys or other heat sources.

Another advantage of using gypsum board for roof sheathing is that it has good sound insulation properties. This makes it an ideal choice for buildings located near busy roads or airports where noise pollution can be an issue.

However, there are also some drawbacks to consider when choosing gypsum board as your roofing material. For example, while it may provide good insulation against sound transmission from outside sources like traffic noise or airplanes flying overhead; however this type of insulation does not work well at blocking sounds generated within the building itself (such as footsteps on upper floors).

Cement Board Sheathing

Made from cement, sand, and cellulose fibers, this type of sheathing is highly resistant to fire and insects. Cement board sheathing can also withstand extreme weather conditions such as hurricanes or tornadoes.

One of the main benefits of using cement board sheathing in roofing projects is that it provides excellent insulation properties. This means that it helps keep your home cool during hot summer months while retaining heat during colder seasons.

Another advantage of using cement board sheathing in roofing projects is its versatility. It can be used with a variety of different types of roofing materials such as asphalt shingles or metal panels.

However, one thing to keep in mind when considering cement board sheathing for your roof project is the weight factor. Cement boards are heavier than other types of roof decking materials like plywood or OSB which may require additional structural support before installation.

Thermoplastic Sheathing

Made from thermoplastic materials such as PVC or TPO, this type of roofing material offers excellent resistance to weather elements, including UV rays and extreme temperatures.

One significant advantage of using thermoplastic sheathing is its ability to reflect sunlight away from the roof’s surface. This reflective property helps reduce heat absorption into your home during hot summer months, resulting in lower cooling costs.

Another benefit of using thermoplastic sheathing is its ease of installation. Unlike traditional roofing materials like plywood or OSB, which require nailing or screwing down onto the framing members beneath them, thermoplastics can be welded together with heat guns for a seamless finish.

However, it’s essential to note that while highly durable and long-lasting when installed correctly by professionals following manufacturer guidelines; improper installation can lead to leaks and other issues over time.

Glass-Mat Sheathing

It is made from fiberglass matting, which is coated with asphalt and then covered with a layer of granules for added protection against UV rays. Glass-Mat Sheathing provides superior strength compared to traditional plywood or OSB sheathings, making it an ideal choice for high-wind areas.

One significant advantage of Glass-Mat Sheathing over other types of roof sheathings is its ability to resist mold growth. This feature makes it an excellent option for homes located in humid climates where mold can be a persistent problem.

Another benefit of using Glass-Mat Sheathing as your roofing material is that it requires less maintenance than other options such as wood or metal roofing materials. Its durable construction ensures long-lasting performance without the need for frequent repairs or replacements.

However, one downside to consider when choosing this type of roof sheathing material may be the cost factor since glass-mat products tend to be more expensive than traditional plywood or OSB options.

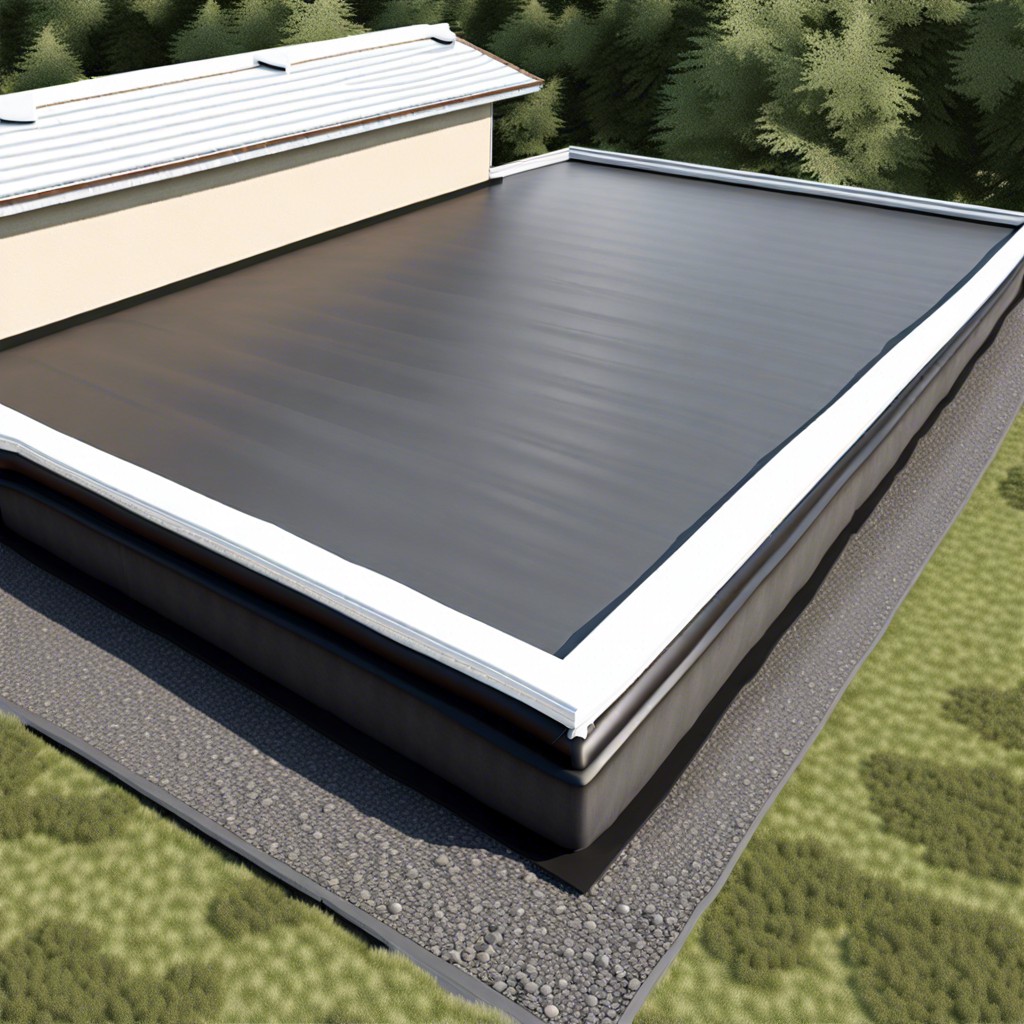

Waterproof Sheathing

Waterproof sheathing is designed to prevent water from penetrating through the roof and causing damage to your home’s interior. It is typically made of materials such as plastic, rubberized asphalt, or a combination of both.

One popular type of waterproof sheathing is known as “peel-and-stick” membrane. This material features a self-adhesive backing that allows it to adhere directly onto the roof deck without any additional fasteners required.

Another type of waterproof sheathing commonly used in commercial buildings and high-end residential homes is liquid-applied membranes. These are applied using spray equipment or rollers and create a seamless barrier against moisture penetration.

Fluted Polypropylene Panels

These panels are made from a corrugated plastic material that is resistant to moisture, chemicals, and UV rays. They come in various thicknesses and sizes, making them suitable for different roofing applications.

One of the significant advantages of fluted polypropylene panels is their ease of installation. They can be easily cut with standard tools such as scissors or knives, making it easy to fit them into any shape or size required by your roofing design.

Another benefit of using fluted polypropylene panels as roof sheathing is their excellent insulation properties. The air pockets created by the corrugations provide an additional layer of insulation against heat loss during winter months while keeping your home cool during summer months.

Concrete Roof Sheathing

It is made of reinforced concrete panels that are typically precast off-site and then installed on the roof structure. Concrete roof sheathing can withstand heavy loads, making it ideal for flat roofs where equipment such as HVAC units may be placed.

One of the main benefits of concrete roof sheathing is its longevity. With proper installation and maintenance, it can last up to 50 years or more without needing replacement.

Because it’s made from non-combustible materials like cement and steel reinforcement bars (rebar), concrete roofing provides excellent fire protection.

However, there are some downsides to using this type of roofing material as well. One major drawback is that it’s very heavy compared to other types of roofing materials like asphalt shingles or metal sheets which means additional structural support may be required during installation.

Skip Roof Sheathing

This type of roofing system was commonly used in older homes and buildings before modern materials were introduced. Skip roof sheathing allows for ventilation and drainage while still providing support for the roofing material.

While skip roof sheathing may not be as common today due to advancements in technology, it can still be found on some roofs. It’s important to note that this type of decking requires careful installation to ensure proper spacing between boards and adequate support for the roofing material.

If you have an older home with skip board sheathing or are considering using this method on a new build project, it’s essential to consult with a professional roofer who has experience working with this particular style of decking. They can help determine if it’s suitable for your specific needs and provide guidance on proper installation techniques.

Wooden Boards Roof Sheathing

It was commonly used in older homes, especially those built before the 1950s. Wooden board sheathing consists of solid wood planks that are nailed to the rafters or trusses to create a flat surface for roofing materials.

While wooden board sheathing has been largely replaced by more modern materials such as plywood and OSB, it still has some advantages over these newer options. For example, wooden boards provide better ventilation than other types of decking because they allow air to circulate between each plank.

However, there are also some downsides to using wooden board sheathing. One major issue is that it can be prone to warping and splitting over time due to exposure from weather elements like rain and sun.

Roof Sheathing Replacement

Over time, roof sheathing can become damaged due to weather elements such as rain, snow, and wind or from pests like termites. When this happens, it’s essential to replace the damaged sections of the roof sheathing promptly.

The first step in replacing your roof sheathing is identifying which areas require attention. This can be done by inspecting your attic for any signs of water damage or rotting wood on the underside of your roofing material.

Once you have identified the problem areas, you will need to remove any shingles or other roofing materials covering them before removing and replacing the damaged sections of roof decking.

It’s important not only to replace rotted wood but also ensure that all new pieces are properly installed with appropriate fasteners according to building codes in order for them not fail prematurely again.

Building Code for Roof Sheathing

When it comes to roof sheathing, building codes specify the type of material, thickness, and installation requirements necessary to ensure a safe and durable roofing system. It is essential to adhere to these guidelines as they help prevent structural failures or collapses due to inadequate support.

The International Building Code (IBC) sets out specific requirements for roof sheathing based on factors such as wind speed, snow load capacity, seismic activity in your area among others. For instance; IBC requires that plywood used for roof decking should be at least 15/32 inches thick while OSB should be at least 7/16 inches thick when installed over rafters spaced not more than 16 inches apart.

It’s important always check with your local building department before installing any new roofing system or replacing an existing one since some areas may have additional code requirements beyond those set by IBC.

Roof Sheathing Dimensions

The thickness and size of the panels can affect the overall strength and stability of your roofing system. Most commonly used roof sheathing materials come in standard sizes, but custom sizes may also be available depending on your specific needs.

Plywood is one of the most popular types of roof sheathing material, and it typically comes in 4′ x 8′ sheets with a thickness ranging from 3/8″ to 3/4″. Oriented Strand Board (OSB) is another common option that usually measures at least four feet wide by eight feet long with a thickness between 7/16″ and 1-1/8″.

It’s important to note that different building codes may require specific minimum dimensions for roof sheathing based on factors such as climate conditions or structural requirements. It’s always best practice to consult local building codes before selecting any type or size of roofing material.

Cost of Roof Sheathing

The type of material used for your roof sheathing will play a significant role in determining its cost. For example, plywood and OSB tend to be more affordable options compared to SIPs or radiant barrier sheathing.

The size and complexity of your roofing project will also impact the overall cost. A larger roof with multiple angles and slopes may require more materials and labor, resulting in higher costs.

It’s important to keep in mind that while opting for cheaper materials may save you money upfront, they may not last as long or provide adequate protection against weather elements like wind-driven rain or snow loads.

Ultimately, investing in high-quality roofing materials such as durable plywood or SIPs can help ensure a longer lifespan for your roof while providing better protection against harsh weather conditions over time.

How Long Does Roof Sheathing Last?

Generally speaking, roof sheathing can last anywhere from 15 to 50 years or more with proper maintenance.

Plywood and OSB are two common types of roof sheathing that have an average lifespan of around 30 years. However, if exposed to moisture or extreme temperatures for extended periods without adequate ventilation or insulation measures in place may shorten their life span significantly.

Fiberboard Sheathing has a shorter lifespan than plywood and OSB due to its susceptibility to water damage. It typically lasts between five to ten years before it needs replacement.

Radiant Barrier Sheathings are relatively new materials designed explicitly for energy efficiency purposes rather than structural support; they can last up to twenty-five years when installed correctly.

The longevity of your roof’s sheathing will depend on several factors beyond the material itself.

Plank Sheathing

It consists of wooden planks, usually made from pine or cedar, which are nailed to the rafters and provide a solid base for roofing materials. Plank sheathing was commonly used in older homes and historic buildings but has since been replaced by more modern types of roof decking.

One advantage of plank sheathing is its durability. When properly installed and maintained, it can last for many years without needing replacement.

Plank sheathing provides excellent ventilation to the attic space below the roof deck.

However, there are also some drawbacks to using plank sheathing as a roofing material. One major disadvantage is that it can be prone to warping over time due to changes in temperature and humidity levels.

Sheet Sheathing

It is made from various materials such as plywood, OSB, and fiberboard. Sheet sheathing provides excellent structural support for the roofing material and helps to distribute weight evenly across the roof’s surface.

One of the benefits of sheet sheathing is its ease of installation. The large size allows for quick installation with fewer seams than smaller pieces would require.

This makes it an ideal choice for larger roofs where time and labor are critical factors.

Another advantage of sheet sheathing is its ability to resist moisture damage when properly installed with adequate ventilation systems in place. Moisture can cause rotting or warping over time if not addressed promptly; however, proper ventilation can help prevent these issues from occurring.

When choosing sheet sheathing for your roofing project, it’s essential to consider factors such as cost-effectiveness and durability based on your specific needs and budget constraints.

Cracks in Roof Sheathing

Cracks can occur due to a variety of reasons, including improper installation, moisture damage, and age-related wear and tear. If left unaddressed, cracks in your roof sheathing can lead to more significant problems such as leaks or even structural damage.

To prevent cracks from forming in your roof sheathing, it’s essential to ensure that the material is installed correctly by a professional roofing contractor. Regular inspections should be conducted on your roofing system to identify any signs of wear and tear before they become major issues.

If you do notice cracks in your roof sheathing during an inspection or otherwise – don’t panic! Depending on the severity of the crack(s), there are several options for repair that may be available. For minor cracking or splitting along seams between sheets (commonly known as “checking”), applying sealant over these areas may suffice.

However if larger splits have formed across multiple panels then replacement will likely be necessary; this process involves removing damaged sections while ensuring proper ventilation throughout so new materials can dry out completely before being installed back into place again – all done under strict building code regulations!.

Water Damage in Roof Sheathing

It can occur due to various reasons, such as heavy rainfall, snow accumulation, or a leaky roof. When water seeps into the sheathing material and remains there for an extended period, it can cause significant damage to your roofing system.

The first sign of water damage in your roof sheathing is usually discoloration or staining on the ceiling inside your home. If left unaddressed for too long, this could lead to mold growth and structural problems.

To prevent water damage from occurring in your roof sheathing, it’s essential to ensure proper installation by a professional roofer who follows building codes and manufacturer guidelines. Regular inspections are also crucial so that any potential issues can be identified early on before they become more severe.

Rotting in Roof Sheathing

Rotting occurs when moisture gets trapped between the roofing material and the sheathing, leading to decay of the wood. This can weaken your roof’s structural integrity and cause it to sag or even collapse.

To prevent rotting, it’s essential to ensure proper ventilation in your attic space. Proper ventilation allows air circulation that helps keep moisture levels low and prevents condensation from forming on the underside of your roof deck.

Regular inspections are also crucial for identifying any signs of rot early on before they become more severe problems. Look out for discoloration or soft spots on your sheathing as these are clear indicators of water damage.

If you suspect that there may be rot present in your roof decking, contact a professional roofer immediately for an inspection and repair services if necessary. Ignoring this issue could lead to costly repairs down the line or even pose safety risks if left unaddressed.

Holes in Roof Sheathing

Holes may occur due to various reasons such as improper installation, animal infestation or natural wear and tear over time. It is essential to address any holes in your roof sheathing promptly.

If you notice any holes or gaps in your roof sheathing, it’s crucial that you have them repaired immediately by a professional roofing contractor. Leaving the issue unaddressed could result in further damage not only to the roofing system but also inside of your home.

The repair process will depend on the size and location of the hole(s). Small holes may be patched with sealant or flashing tape while larger ones require more extensive repairs such as replacing damaged sections of plywood or OSB boards.

Sagging in Roof Sheathing

When the roof sheathing sags or dips in certain areas, it can cause the roofing material to buckle or crack under pressure. This not only compromises your home’s structural integrity but also puts you at risk of water damage during heavy rainfall.

If you notice any signs of sagging in your roof sheathing such as visible dips or unevenness on your ceiling surface from inside the house, it’s crucial to address them immediately before they worsen over time. A professional roofer can inspect your roofing system for underlying issues causing sagging and recommend appropriate repairs.

In some cases where severe damage has occurred due to prolonged neglect or improper installation practices initially used by contractors who installed the original roofing system; replacement may be necessary instead of repair work alone. It is essential always to ensure that proper care is taken when installing new roofs so that future problems like this do not arise again down-the-line.

Comparing OSB and CDX Plywood

Both materials have their unique features that make them suitable for different roofing applications.

OSB (Oriented Strand Board) is a type of engineered wood made from strands or flakes of wood that are glued together under high pressure and heat. It is known for its strength, durability, and affordability compared to other types of roof sheathing.

OSB also has excellent moisture resistance properties due to its wax coating on the surface.

On the other hand, CDX plywood is a traditional option made from thin layers or plies of wood veneer that are glued together in alternating directions. The “C” stands for one side being graded as “C-grade,” while the opposite side receives a lower grade (“D”).

This type of plywood offers better dimensional stability than OSB but may not be as strong when exposed to moisture over time.

When comparing these two materials’ cost-effectiveness, OSB tends to be more affordable than CDX plywood due to its manufacturing process’s efficiency. However, if you’re looking for long-term durability with minimal maintenance requirements in areas with high humidity levels or frequent exposure to water such as coastal regions where hurricanes occur frequently – then choosing CDX Plywood might be your best bet.

Exterior Gypsum Board

It is made from gypsum, which is a soft sulfate mineral composed of calcium sulfate dihydrate. Exterior Gypsum Board offers several benefits over traditional plywood or OSB sheathing, including superior fire resistance and moisture resistance.

One significant advantage of Exterior Gypsum Board as roof sheathing material is its ability to resist mold growth and rotting caused by water damage. This makes it an ideal choice for areas with high humidity levels or frequent rainfall.

Another benefit of using Exterior Gypsum Board as roof sheathing material is its excellent sound insulation properties. It can help reduce noise transmission between floors, making it an attractive option for multi-story buildings such as apartments or condominiums.

However, one downside to using exterior gypsum board as roofing material compared to other types like plywood or OSB boards are the cost implications; they tend to be more expensive than other options available in the market today.

How Often Should Roof Sheathing Be Replaced?

Over time, roof sheathing can deteriorate due to exposure to weather elements such as rain, snow, and wind. It can also be damaged by pests or foot traffic during maintenance work on the roof.

So how often should you replace your roof sheathing? The answer depends on several factors such as the type of material used for the sheathing and its age. In general, most types of roof sheathing have a lifespan ranging from 15-30 years.

However, if you live in an area with harsh weather conditions or frequent storms that cause damage to your roofing system regularly; then you may need more frequent replacements than someone living in a milder climate.

It’s crucial always to inspect your roofing system regularly for any signs of wear and tear or damage. If there are visible cracks or holes in the surface layer of your shingles/roofing material (or water stains inside), this could indicate underlying issues with rotting wood underneath which would require immediate attention before further deterioration occurs.

Spotting Rotted Roof Decking

This can occur due to water damage, poor ventilation, or age. Rotted roof decking can compromise the structural integrity of your roofing system and pose a safety hazard to you and your family.

To spot rotted roof decking, start by inspecting your attic for any signs of water damage or leaks. Look for discoloration on the ceiling or walls as well as mold growth in corners and crevices.

Next, climb onto your rooftop (if it’s safe) and examine the surface carefully. Check for soft spots underfoot that may indicate rotting wood beneath them.

You should also look out for cracks in shingles or tiles that could allow moisture to seep through into the underlying layers.

If you suspect that there is rotted decking present on your rooftop after conducting these inspections, it’s best to call a professional roofing contractor immediately before further damage occurs.

Code Regulations for Roof Sheathing

Building codes vary from state to state and may also depend on the type of building being constructed or renovated. It’s essential to consult with a professional roofer who understands local building codes before installing any type of roof sheathing.

One common code regulation for roof sheathing is its thickness. The International Residential Code (IRC) requires that plywood or OSB used as roof decking should be at least 15/32 inches thick if it spans 16 inches on center or less and at least ½ inch thick if it spans more than 16 inches on center.

Another important code regulation concerns ventilation requirements for attics where the roofing system is installed over solid wood sheathing. Proper attic ventilation helps prevent moisture buildup, which can lead to mold growth and other issues that compromise indoor air quality.

Inspecting Roof Decking

Over time, the decking can become damaged due to weather elements such as rain, snow, and wind. It’s crucial to inspect your roof decking regularly for any signs of damage or wear and tear that could compromise the integrity of your entire roofing system.

During an inspection, you should look for any cracks or holes in the sheathing material. These can be caused by water damage or pests such as termites and rodents.

You should also check for sagging areas in the roof deck which may indicate structural issues.

Another thing to keep an eye out for is rotting wood on wooden boards sheathing systems which are more prone to decay over time if not properly maintained.

If you notice any signs of damage during your inspection, it’s important to address them promptly before they worsen and lead to more significant problems down the line.

Regular inspections are critical when it comes to maintaining a healthy roofing system with proper functioning components like good quality roof sheathing materials that provide stability while protecting against harsh weather conditions all year round!.

FAQ

What is the best sheathing for a roof?

The best sheathing for a roof is OSB (oriented strand board), as it is the most popular choice today.

Should roof sheathing be CDX or OSB?

Answer: Many experts argue that OSB is better overall for roofing due to its reduced expansion and contraction when exposed to humidity and moisture, despite taking longer to dry.

What is the difference between OSB and CDX roof?

The difference between OSB and CDX roof is that OSB (Oriented Strand Board) is made of chips pressed together with resin, while CDX is made of 3-to-8 thin plies of wood layered together to form one sheet, often considered "real plywood."

What are the advantages and disadvantages of using CDX plywood vs. OSB for roof sheathing?

CDX plywood offers better moisture resistance and stiffness, while OSB generally costs less and is more environmentally friendly.

How does the thickness of roof sheathing affect the overall performance and durability of a roofing system?

Roof sheathing thickness affects the overall performance and durability of a roofing system by providing increased strength, stability, and resistance to weather-related damage.

How do weather conditions and climate impact the choice of roof sheathing materials?

Choice of roof sheathing materials is significantly influenced by weather conditions and climate, as they must endure various environmental factors like temperature fluctuations, moisture levels, and extreme weather events.