Last updated on

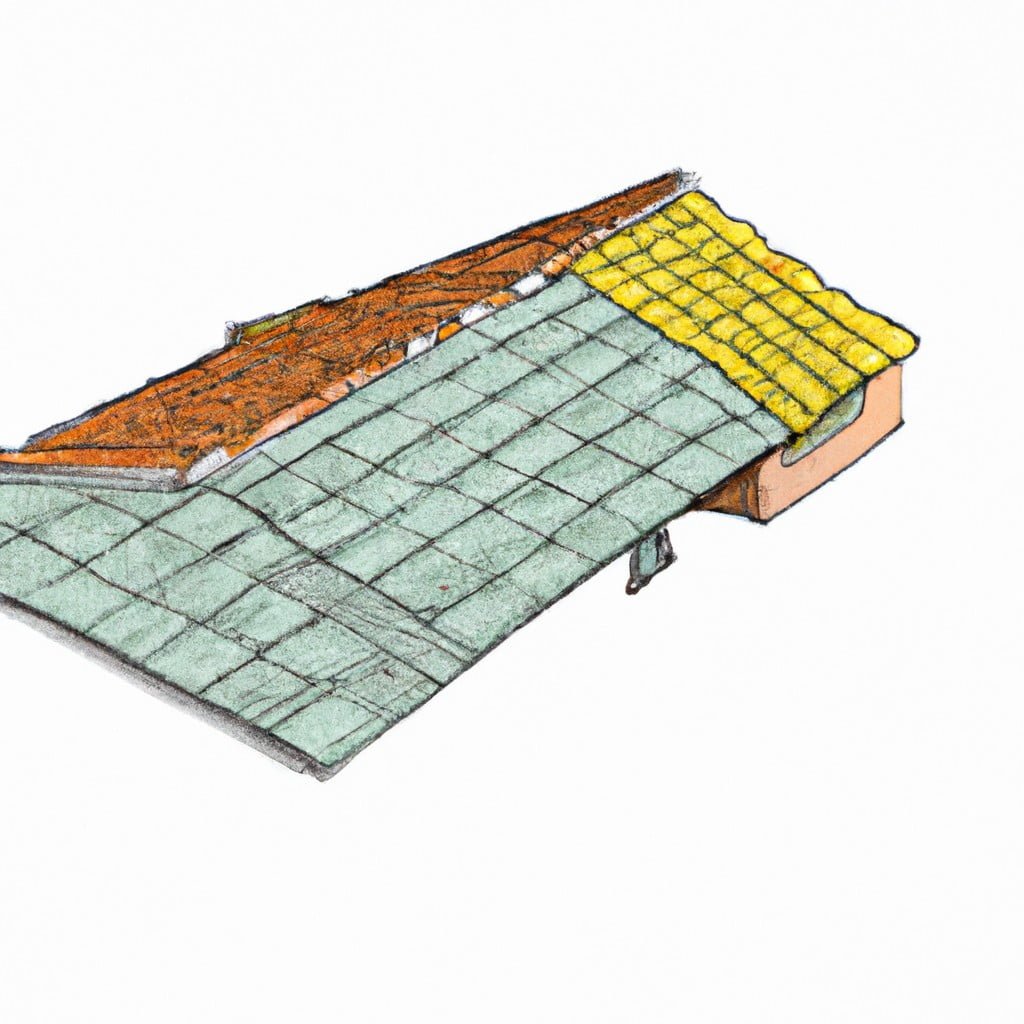

Explore the diverse world of roof sheeting profiles as we delve into their unique characteristics, benefits, and applications for your next construction project.

When it comes to roofing, there are a variety of options available to homeowners and builders. One important aspect of roofing is the type of sheeting profile used.

The right profile can not only enhance the look of a building but also provide better protection against weather elements. From corrugated to standing seam, there are several types of roof sheeting profiles that you can choose from depending on your needs and preferences.

In this article, we will explore some popular types of roof sheeting profiles and their benefits so that you can make an informed decision when it comes to your roofing project.

Corrugated Roofing Sheets

These sheets have a distinctive wavy pattern that provides excellent water shedding capabilities while also adding an attractive texture to the roof. Corrugated roofing sheets are typically made from metal or fiberglass materials.

Metal corrugated roofing sheets come in different types such as galvanized steel, aluminum, copper or zinc-coated steel. They offer superior strength and longevity compared to other materials making them ideal for harsh weather conditions like heavy rainfalls or snowstorms.

Fiberglass corrugated roofing sheets on the other hand provide good insulation properties which make them suitable for areas with extreme temperatures such as hot summers or cold winters.

Metal Roofing Sheets

They come in various profiles such as corrugated, standing seam, R-panel among others. Metal roofing sheets can be made from different materials including steel, aluminum or copper.

Steel is the most commonly used material for metal roofing sheets due to its strength and affordability. It is also available in a variety of finishes such as galvanized steel which has been coated with zinc to prevent rusting.

Aluminum metal roofing sheets are lightweight yet strong making them ideal for areas prone to hurricanes or high winds. They do not rust but may corrode over time if exposed to saltwater environments.

Copper metal roofing sheets have an attractive appearance that improves with age as they develop a natural patina over time. However, they are more expensive than other types of metal roofs.

Fiberglass Roofing Sheets

They are made of glass fibers that have been woven together to create a strong and lightweight material. Fiberglass roofing sheets come in different profiles such as corrugated or flat panels.

One of the main advantages of fiberglass roofing sheets is their resistance to corrosion, which makes them ideal for areas with high humidity or saltwater exposure. They also offer excellent insulation properties that can help reduce energy costs by keeping your home cooler in summer and warmer in winter.

Another benefit is their ease of installation due to being lightweight compared to other materials like metal or concrete tiles. This means less labor time required during installation resulting in lower overall project cost.

However, it’s important to note that fiberglass roofing sheets may not be suitable for areas with heavy snowfall as they can crack under pressure from the weight of snow accumulation over time.

Polycarbonate Roofing Sheets

These sheets are made from polycarbonate polymer and can be used in various applications such as skylights, greenhouses, patios, carports and more. They come in different colors including clear or opaque options that allow natural light to pass through while still providing protection against UV rays.

One of the main advantages of using Polycarbonate Roofing Sheets is their resistance to impact damage which makes them ideal for areas prone to hailstorms or heavy rainfall. They have excellent thermal insulation properties which help regulate temperature inside buildings during extreme weather conditions.

However, it’s important to note that Polycarbonate Roofing Sheets may not be suitable for all climates as they tend to expand and contract with temperature changes leading them susceptible cracking over time if not installed correctly. It’s also essential that proper installation techniques are followed when installing these sheets since any gaps between panels could lead water infiltration into the building structure.

Bitumen Roofing Sheets

Made from asphalt, these sheets come in various thicknesses and can be reinforced with fiberglass or polyester to increase their strength. Bitumen roofing sheets are easy to install, making them an ideal option for DIY projects.

One of the main advantages of bitumen roofing is its affordability compared to other materials like metal or slate. It also has a long lifespan, lasting up to 20 years with proper maintenance.

However, one disadvantage of bitumen roofing is that it can become brittle over time due to exposure from UV rays which may cause cracking and leaks if not maintained properly. They may not be suitable for areas prone to extreme weather conditions such as heavy snowfall or hailstorms.

Slate and Tile Roofing Sheets

These roofing sheets are made from natural materials such as slate, clay, or concrete tiles that offer durability and longevity. Slate is known for its unique texture and color variations while tile offers a range of colors, shapes, and sizes.

One advantage of using slate or tile roofing sheets is their ability to withstand harsh weather conditions such as heavy rainstorms or hailstorms. They also have excellent fire resistance properties which make them ideal for areas prone to wildfires.

However, one disadvantage of these types of roof sheeting profiles is the high cost associated with installation compared to other options like corrugated metal roofs. They require specialized skills during installation due to their weight which can be challenging if not handled by professionals.

Solar Roofing Sheets

These sheets are designed with integrated photovoltaic cells that convert sunlight into electricity, which can be used to power your home or business. Solar roofing sheets come in a variety of profiles and colors, making them a versatile option for any building design.

One of the main advantages of solar roofing is its ability to reduce energy costs over time. By generating your own electricity from the sun’s rays, you can significantly lower your monthly utility bills while also reducing carbon emissions.

However, it’s important to note that installing solar panels on your roof requires careful planning and installation by professionals who specialize in this type of work. Not all roofs may be suitable for solar panel installation due to factors such as shading or structural limitations.

Standing Seam Roofing Sheets

They feature raised seams that interlock to create a watertight seal, making them ideal for areas with heavy rainfall or snowfall. These roofing sheets come in various materials such as aluminum, steel, copper and zinc which offer different advantages depending on the application.

One of the main benefits of standing seam roofing sheets is their durability. They can withstand extreme weather conditions including high winds and hailstorms without sustaining damage or leaks.

They require minimal maintenance over their lifespan due to their resistance to corrosion.

Another advantage of standing seam roofing sheets is their aesthetic appeal. The clean lines created by the raised seams give buildings a modern look that complements contemporary architecture styles perfectly.

Installation of these types of roof sheeting profiles requires specialized equipment and expertise; therefore it’s important to hire experienced professionals who have worked with this type before.

R-panel Roofing Sheets

These panels have a trapezoidal profile with high ribs that provide excellent water shedding capabilities. R-panel roofing sheets are made from galvanized steel or aluminum which makes them resistant to rusting and corrosion.

One of the main advantages of R-panel roofing sheets is their ease of installation. They can be installed quickly over large areas without requiring any special tools or equipment.

This makes them an ideal option for projects with tight deadlines.

Another benefit is that they require minimal maintenance once installed properly, making them a low-maintenance solution for building owners who want to save on repair costs in the long run.

However, it’s important to note that while R-panels offer great value in terms of affordability and longevity, they may not be suitable for all types of buildings or climates. It’s essential to consider factors such as wind uplift resistance when selecting this type of roof sheeting profile.

CUSTOM ORB®

It is known for its distinctive corrugated shape and versatility, making it suitable for both residential and commercial roofing applications. The CUSTOM ORB® profile features deep ribs that provide excellent water shedding capabilities, making it ideal for areas with heavy rainfall or snowfall.

One advantage of using CUSTOM ORB® as your roofing material is its durability. Made from high-quality steel, this profile can withstand harsh weather conditions such as strong winds and hailstorms without sustaining damage.

The ribbed design provides added strength to the structure while also reducing noise levels during rainfalls.

Another benefit of choosing CUSTOM ORB® is its aesthetic appeal. This classic Australian design adds character to any building while also providing a timeless look that never goes out of style.

When selecting a roof sheeting profile like CUSTOM ORB®, there are several factors to consider such as climate conditions in your area, installation process requirements and maintenance needs among others.

TRIMDEK®

It is a versatile and durable option that can be used for both residential and commercial buildings. TRIMDEK® sheets are made from high-quality steel, which makes them strong enough to withstand harsh weather conditions such as heavy rain, hailstorms, and strong winds.

One of the benefits of using TRIMDEK® sheets is their ease of installation. They come in different lengths depending on your needs, making it easy to install them quickly without any hassle or complications.

Another advantage of TRIMDEK® sheets is their low maintenance requirements. They do not require regular painting or coating like other roofing materials since they are already coated with zincalume for added protection against corrosion.

SPANDEK®

It is made from high-tensile steel and features a unique trapezoidal rib design that provides excellent strength and durability. The profile’s wide cover width also means fewer sheets are required to cover the same area, making it an economical choice for roofing.

One of the key benefits of SPANDEK® is its versatility. It can be used for both roofing and wall cladding applications, making it ideal for commercial buildings such as warehouses or factories where both functions may be required.

Another advantage of SPANDEK® is its ease of installation. Its lightweight nature makes it easy to handle on-site, while its concealed fixing system ensures a clean finish without any visible screws or fasteners.

However, like all roof sheeting profiles, there are some disadvantages to consider when choosing SPANDEK® as your roofing material. For example, due to its metal composition, noise levels during heavy rain or hailstorms may be higher compared with other materials such as fiberglass or polycarbonate sheets.

KLIP-LOK 700 HI-STRENGTH®

It is made from high-tensile steel, which makes it resistant to corrosion and weather elements such as hail, wind, and rain. This roofing profile has concealed fixings that provide a clean finish while also preventing water ingress.

The KLIP-LOK 700 HI-STRENGTH® roofing system can be used for both residential and commercial buildings with low-pitched roofs. Its unique design allows for easy installation without the need for additional sealants or adhesives.

One advantage of using KLIP-LOK 700 HI-STRENGTH® is its ability to withstand extreme weather conditions such as cyclones or hurricanes due to its interlocking mechanism that provides added strength against uplift forces.

Another benefit of this roofing system is its energy efficiency properties. The concealed fixings reduce heat transfer through the roof surface resulting in lower cooling costs during hot summer months.

KLIP-LOK CLASSIC® 700

It is known for its strength, durability, and versatility. This profile features concealed fastening clips that provide a clean finish to the roof while also ensuring water-tightness.

The KLIP-LOK CLASSIC® 700 roofing sheets are made from high-quality steel or aluminum material which makes them resistant to corrosion and weather elements such as hailstorms, heavy rainfalls, and strong winds. They come in different colors and finishes which can be customized according to your preferences.

One of the advantages of using KLIP-LOK CLASSIC® 700 roofing sheets is their ease of installation due to their interlocking design with no exposed screws or fasteners required during installation. This not only saves time but also reduces the risk of leaks occurring on your roof.

Another benefit of this type of roofing sheeting profile is its ability to withstand extreme temperatures without warping or cracking over time. Whether you live in an area with hot summers or cold winters, KLIP-LOK CLASSIC® 700 will maintain its structural integrity throughout all seasons.

CUSTOM BLUE ORB®

It is made from high-quality steel and coated with a durable paint finish, making it resistant to corrosion and fading. The CUSTOM BLUE ORB® profile features deep ribs that provide excellent water shedding capabilities, ensuring your roof remains leak-free even during heavy rainfall.

This type of roofing sheeting profile is ideal for commercial buildings such as warehouses, factories or agricultural sheds due to its strength and durability. The CUSTOM BLUE ORB® can be customized according to your specific requirements in terms of length, color or thickness.

When selecting the right roof sheeting profiles for your project needs careful consideration should be given not only on aesthetics but also on functionality and durability.

KLIP-LOK® 406

It features concealed fastening, which means that the screws are not visible on the surface of the sheet, giving it a sleek and modern look. This profile is ideal for commercial buildings with low-pitched roofs as it can handle heavy rainfall without leaking.

The KLIP-LOK® 406 profile has been designed to withstand harsh weather conditions such as high winds and hailstorms. Its unique design allows for thermal expansion and contraction, making it suitable for areas with extreme temperature changes.

One advantage of using KLIP-LOK® 406 is its ease of installation due to its clip fixing system. The clips allow for quick installation while ensuring proper alignment between sheets.

Another benefit of this roofing profile is its versatility in terms of material options such as steel or aluminum, allowing you to choose what best suits your needs based on factors like budget or environmental considerations.

CUSTOM ORB ACCENT® 21

This profile features a unique rib design that adds depth and dimension to the roof while also providing excellent water shedding capabilities. The CUSTOM ORB ACCENT® 21 is made from high-quality steel with a zinc/aluminum alloy coating which provides superior corrosion resistance.

One of the benefits of using CUSTOM ORB ACCENT® 21 for your roofing project is its versatility in terms of color options. You can choose from a wide range of COLORBOND® steel colors or opt for powder-coated finishes to match your building’s aesthetic requirements.

Another advantage offered by this profile is its ease of installation due to its lightweight nature compared to other profiles such as tiles or slate. It requires minimal maintenance once installed properly.

FLATDEK®

It features wide, flat pans with no ribs or corrugations, making it an ideal choice for contemporary designs. FLATDEK® is made from high-quality steel and comes in various thicknesses to suit different applications.

One of the advantages of FLATDEK® roofing sheets is their ease of installation. They are designed to be installed quickly and efficiently, reducing labor costs and project timelines.

They require minimal maintenance once installed.

Another benefit of FLATDEK® roofing sheets is their versatility in terms of color options. They can be coated with a range of colors using advanced paint technology that provides long-lasting protection against fading or chalking due to exposure to sunlight.

FLATDEK® II

It is made from high-quality steel, which makes it resistant to corrosion and weather elements. The FLATDEK® II profile has a flat surface with wide pans that provide an attractive finish for any building design.

One of the benefits of using FLATDEK® II roofing sheets is its ease of installation. The sheets are designed to interlock seamlessly, making them easy to install without requiring special tools or equipment.

This feature also ensures that there are no gaps between the panels, providing better protection against water leaks.

Another advantage of FLATDEK® II roofing sheets is their low maintenance requirements. They do not require frequent cleaning or painting like other types of roofs since they have a smooth surface that does not accumulate dirt easily.

LOK-KLIP®

It features concealed fasteners, which provide a sleek and modern look to any building. The LOK-KLIP® profile is designed with high ribs that interlock tightly, creating an impenetrable barrier against water, wind, and other elements.

This roofing system is ideal for commercial buildings as it can withstand heavy loads without compromising its structural integrity. The LOK-KLIP® profile has been tested to meet stringent industry standards for fire resistance.

One of the benefits of using this type of roof sheeting profile is its ease of installation. With fewer components required during installation compared to traditional roofing systems like tiles or shingles; it saves time on labor costs while still providing superior performance.

TRIM-KLIP®

It is made from high-quality steel, which makes it resistant to corrosion and weather elements. The TRIM-KLIP® profile features a unique design that allows for easy installation without the need for additional fasteners or clips.

One of the main advantages of using TRIM-KLIP® roofing sheets is their versatility in application. They can be used on both residential and commercial buildings, as well as industrial structures such as warehouses or factories.

Another benefit of this type of roofing sheeting profile is its low maintenance requirements. Once installed correctly, it requires minimal upkeep over time compared to other types of roofing materials like tiles or shingles.

If you are looking for an affordable yet durable option when choosing your next roof sheeting material, then consider TRIM-KLIP® profiles.

MINI ORB®

It is a corrugated profile with smaller and tighter curves than the traditional corrugated sheets, giving it an attractive appearance. MINI ORB® roofing sheets are made from high-quality steel and come in different colors to match your building’s design.

One of the benefits of using MINI ORB® roofing sheets is their durability. They can withstand harsh weather conditions such as heavy rain, strong winds, and hailstorms without getting damaged easily.

This makes them ideal for buildings located in areas prone to extreme weather conditions.

Another advantage of using MINI ORB® roofing sheets is their versatility. They can be used for both residential and commercial buildings due to their aesthetic appeal and functionality features like water resistance, fire resistance among others.

When installing this type of roof sheeting profile on your building project ensure you follow manufacturer instructions or hire professional installers who have experience working with this material.

MULTICLAD®

It is made from high-quality steel, which makes it resistant to corrosion and weather damage. The profile features a ribbed design that enhances its strength while also providing an attractive finish for your roofing project.

One of the benefits of MULTICLAD® is its flexibility in terms of application. It can be used for both residential and commercial buildings, as well as industrial structures such as warehouses or factories.

Its ability to withstand harsh weather conditions makes it ideal for areas prone to heavy rainfall or strong winds.

Another advantage of MULTICLAD® is its ease of installation compared to other types of roof sheeting profiles. This means you can save time and money on labor costs during the construction process without compromising on quality.

When selecting a roof sheeting profile, it’s important to consider factors such as cost-effectiveness, durability, aesthetics, environmental impact among others depending on your needs and preferences.

PANELRIB®

It features deep ribs that provide superior water shedding capabilities, making it ideal for areas with heavy rainfall or snowfall. The PANELRIB® profile is available in a range of materials such as steel, aluminum, and zincalume to suit different applications.

One of the key advantages of PANELRIB® roofing sheets is their versatility. They can be used for both residential and commercial buildings due to their aesthetic appeal and functionality.

They are easy to install thanks to the interlocking design which ensures quick installation without compromising on quality.

Another benefit of using PANELRIB® roofing sheets is its low maintenance requirements compared to other types of roof sheeting profiles like tile or slate roofs which require regular cleaning due to moss buildup or debris accumulation.

In terms of cost-effectiveness, PANELRIB® roofing sheets offer great value for money as they are relatively affordable compared with some high-end options like standing seam metal roofs while still providing similar benefits such as durability and longevity.

WALLCLAD®

It features a ribbed profile with wide cover and can be installed both horizontally and vertically, making it versatile in its application. This roofing material comes in different thicknesses, ranging from 0.35mm to 0.60mm, which makes it suitable for various building types.

One of the advantages of WALLCLAD® is its durability as it can withstand harsh weather conditions such as heavy rainfalls or strong winds without getting damaged easily. This roofing material requires minimal maintenance due to its resistance to corrosion and rust.

Another benefit of using WALLCLAD® for your construction project is that it provides excellent thermal insulation properties which help regulate temperature inside the building by keeping heat out during hot seasons while retaining warmth during cold seasons.

In terms of aesthetics, WALLCLAD® offers an attractive finish with a range of color options available so you can choose one that complements your building’s design scheme perfectly.

TRIMWALL®

It is made from high-quality steel, which makes it strong enough to withstand harsh weather conditions such as heavy rain, snowfall, and hailstorms. TRIMWALL® has a unique ribbed design that provides extra strength while also enhancing the aesthetic appeal of any building.

One of the key benefits of TRIMWALL® is its versatility in terms of application. It can be used for both roofing and wall cladding purposes, making it an ideal choice for commercial buildings with large facades or residential homes with unique architectural designs.

Another advantage of TRIMWALL® is its ease-of-installation due to its lightweight nature compared to other roofing materials like tiles or slate. This means less time spent on installation resulting in lower labor costs.

When selecting a roof sheeting profile like TRIMWALL®, there are several factors you need to consider such as climate conditions in your area, maintenance requirements over time and cost-effectiveness among others.

WEATHERLINE®

It is made from high-quality steel, which makes it resistant to corrosion, rust, and other forms of damage caused by harsh weather conditions. This roofing profile has a unique design that allows for easy installation while providing excellent water shedding capabilities.

One of the main advantages of WEATHERLINE® is its ability to withstand extreme temperatures without cracking or warping. This makes it an ideal choice for areas with hot summers or cold winters where other roofing materials may fail.

Another benefit of WEATHERLINE® is its versatility in terms of color options and finishes. You can choose from a range of colors to match your building’s aesthetic appeal while also benefiting from the practical features this roof sheeting profile provides.

Roof Sheeting Material Advantages

Here are some advantages associated with different types of roof sheeting materials:.

1. Metal Roofing Sheets: Metal sheets are durable, long-lasting, and require minimal maintenance.

They also offer excellent resistance to fire, wind, and hail damage.

2. Fiberglass Roofing Sheets: Fiberglass sheets are lightweight yet strong enough to withstand harsh weather conditions such as heavy rain or snowfall.

3. Polycarbonate Roofing Sheets: Polycarbonate is a versatile material that offers high impact resistance while allowing natural light into the building.

4. Bitumen Roofing Sheets: Bitumen sheets provide excellent waterproof properties making them ideal for areas with high rainfall or humidity levels.

5. Slate and Tile Roof Sheetings: Slate tiles offer an attractive appearance while being highly resistant to fire damage whereas tile roofs provide good insulation against heat loss in colder climates.

Roof Sheeting Material Disadvantages

One disadvantage of metal roofing sheets is that they can be noisy during heavy rain or hailstorms. Fiberglass and polycarbonate roofing sheets may discolor over time due to exposure to UV rays, which can affect the aesthetic appeal of your building.

Bitumen roofing sheets are prone to cracking in extreme temperatures and require regular maintenance.

Slate and tile roofing sheets are heavy, making them unsuitable for some buildings without additional structural support. Solar panels integrated into roof sheeting profiles may increase the cost significantly compared with other types of roofs.

Roof Sheeting Profile Selection Criteria

One of the most important is the climate in which you live. For example, if you live in an area with high winds or heavy snowfall, a standing seam or R-panel roofing sheet may be more suitable than corrugated sheets.

Another factor to consider is the slope of your roof; some profiles work better on steeper roofs while others are better suited for flatter roofs.

The material used for your roofing sheets also plays a significant role in determining their suitability for different applications and environments. Metal roofing sheets offer excellent durability and resistance against harsh weather conditions but can be noisy during rainstorms without proper insulation.

Fiberglass and polycarbonate roofing sheets provide good light transmission but may not hold up well under extreme temperatures or hailstorms.

Slate and tile roofing sheets offer superior aesthetics but can be expensive compared to other options like bitumen or metal panels.

Ultimately, it’s essential to choose a profile that meets both functional requirements such as durability, weather-resistance as well as aesthetic preferences such as color scheme compatibility with surrounding structures.

Roof Sheeting Installation Process

The installation process can vary depending on the type of roofing material and profile chosen. It is important to follow manufacturer instructions carefully and hire a professional if necessary.

For corrugated metal roofing sheets, start by measuring the length of your roof from end to end. Cut each sheet according to this measurement using tin snips or a circular saw with a metal-cutting blade.

Install each sheet starting at one corner of the roof and working across in rows until complete.

Fiberglass roofing sheets are installed similarly but require special care when cutting as they can easily crack or splinter if not handled properly.

Polycarbonate roofing sheets may require pre-drilling holes before installation due to their tendency towards expansion under heat exposure.

Standing seam roofs involve interlocking panels that snap together without any exposed fasteners, making them more weather-resistant than other types of profiles but also requiring specialized equipment for proper installation.

Regardless of which type you choose, always ensure that safety measures are taken during installation such as wearing protective gear like gloves and goggles while handling sharp materials like metal or fiberglass.

Maintenance of Roof Sheeting Profiles

Regular inspections should be conducted to identify any signs of damage or wear and tear, such as cracks, leaks, or rust. It’s important to address these issues promptly before they worsen and cause more significant problems.

Cleaning your roof sheeting profiles is also crucial for their upkeep. Dirt, debris, leaves can accumulate on the surface over time which can lead to water pooling in certain areas causing corrosion or even leakage into the building interior.

To clean your roofing sheets effectively without damaging them requires a gentle approach using mild detergents with low-pressure washing equipment that won’t scratch off protective coatings from metal roofs.

Environmental Considerations for Roof Sheeting

Some roofing materials are more eco-friendly than others and can help reduce your carbon footprint. For instance, metal roofing sheets are recyclable and can be reused for other purposes after their lifespan is over.

Fiberglass sheets also have a low environmental impact as they do not contain harmful chemicals or substances that could harm the environment.

Polycarbonate roofing sheets, on the other hand, may not be as environmentally friendly due to their manufacturing process which involves toxic chemicals such as Bisphenol A (BPA). Bitumen roofing sheets also pose an environmental risk because they release volatile organic compounds (VOCs) into the air during installation.

Slate and tile roofs are considered sustainable options since they’re made from natural materials that don’t require much energy to produce. Solar panels integrated into roof sheeting profiles provide renewable energy while standing seam roofs offer excellent insulation properties reducing heating costs in winter months.

Roof Sheeting for Different Climates

Different climates require different types of roofing materials and profiles that can withstand extreme weather conditions. For instance, in areas with high rainfall or snowfall, corrugated metal sheets are ideal as they have a steep slope that allows water and snow to slide off easily.

In hot and humid regions, polycarbonate roofing sheets are preferred as they offer excellent heat resistance while allowing natural light into the building.

In coastal areas where there is high salt content in the air due to sea spray or ocean winds, standing seam metal roofs are recommended because of their durability against corrosion caused by saltwater exposure.

For regions prone to wildfires such as California’s wildfire-prone zones or Australia’s bushfire-prone areas; homeowners should consider using fire-resistant roof sheeting profiles like Colorbond steel which has been tested for its ability to resist ember attacks from bushfires.

Comparing Roof Sheeting Profiles

One of the most important is comparing different profiles and their features. Each type of roofing material has its own advantages and disadvantages, so it’s essential to weigh them against each other before making a decision.

For example, corrugated roofing sheets are popular due to their affordability and durability but may not be as aesthetically pleasing as standing seam or tile roofing sheets. Metal roofing sheets offer excellent weather resistance but can be noisy during heavy rainfalls.

Fiberglass and polycarbonate sheeting provide natural light transmission while being lightweight yet durable enough for harsh weather conditions. Bitumen sheeting is an affordable option that provides good insulation properties but may require more maintenance than other materials.

Slate and tile roofs have been used for centuries due to their longevity, fire resistance, energy efficiency properties; however they can be expensive upfront costs compared with metal or fiberglass options which have lower installation costs over time because they last longer without needing repairs like slate tiles do!.

Roof Sheeting Profile Accessories

These accessories include ridge caps, barge capping, flashings, gutters and downpipes.

Ridge caps are used at the peak of a roof where two slopes meet. They provide an attractive finish while also protecting against water penetration.

Barge capping is installed on the edge of a gable or skillion roof to protect against weather elements such as wind-driven rain.

Flashings are installed around chimneys or other protrusions in order to prevent water from seeping into gaps between roofing materials and these structures.

Gutters and downpipes collect rainwater from roofs for storage or drainage purposes. They come in different shapes and sizes depending on your needs.

Roof Sheeting Warranties and Guarantees

Roof sheeting profiles come with different warranty periods depending on the manufacturer and material used. It is essential to understand what your warranty covers before making a purchase decision.

Most manufacturers offer warranties that cover defects in materials or workmanship for a specific period, usually ranging from 10-50 years. Some also provide additional coverage against weather damage such as hail or windstorms.

It’s crucial to read the fine print of any warranty carefully so that you know exactly what is covered and under which circumstances you can make claims. For instance, some warranties may only cover repairs while others may include replacement costs as well.

It’s worth noting that not all roofing contractors honor manufacturer warranties if they did not install the roof correctly or use approved installation methods/materials. Therefore, ensure that your contractor has experience installing your chosen profile type before hiring them for the job.

Understanding roofing product warranties will help you make informed decisions when selecting roof sheeting profiles for your project while giving peace of mind knowing there’s protection against unforeseen issues down the line after installation completion.

Roof Sheeting Fire Resistance

Some materials are more fire-resistant than others, and this can make all the difference in protecting your property from potential fires. Metal roofing sheets, for example, are highly resistant to fire and can help prevent flames from spreading throughout a building.

Fiberglass roofing sheets also have good fire resistance properties due to their composition of glass fibers that do not burn easily.

On the other hand, bitumen roofing sheets may be less resistant to fires as they contain petroleum-based products that can ignite quickly if exposed to high temperatures or flames. It’s important always to check with manufacturers about their product’s specific fire rating before making any purchase decisions.

When it comes down selecting a roof sheeting profile based on its level of flame retardancy or resistance against heat damage caused by wildfires or other sources such as sparks emanating from chimneys during winter months; you should consult with an expert roofer who will guide you through various options available in terms of material type and thicknesses suitable for different climates while keeping safety concerns at top priority.

Cost of Roof Sheeting Profiles

The price of a roofing material depends on various factors such as its durability, quality, and availability. Some materials like metal and polycarbonate are more expensive than others like fiberglass or bitumen.

However, it’s essential to keep in mind that investing in high-quality roofing materials can save you money in the long run by reducing maintenance costs and increasing energy efficiency. Some types of roof sheeting profiles may require specialized installation techniques or accessories which can add up to the overall cost.

It’s always advisable to get quotes from different suppliers before making a final decision on your preferred type of roof sheeting profile. This will help you compare prices and choose one that fits within your budget without compromising on quality.

Roof Sheeting Profile Customization

It allows you to create a unique look for your building while also ensuring that the roofing material meets your specific needs and requirements. Many manufacturers offer customization options, such as color choices, coatings, and finishes.

You can even have custom shapes or sizes made to fit the exact specifications of your project.

When it comes to customization options for roof sheeting profiles, there are several factors that you should consider before making a decision. These include the type of material used in the profile’s construction, its durability and strength properties as well as its resistance against weather elements like wind or hail damage.

It’s essential to work with experienced professionals who can guide you through this process so that you get exactly what you need from your customized roofing solution without compromising on quality or performance standards.

When selecting a roof sheeting profile for any construction project – whether residential or commercial – it is crucial to take into account all available types along with their advantages and disadvantages carefully.

FAQ

What are the different types of roofing iron profiles?

Different types of roofing iron profiles include Corrugate, Trapezoidal, and Tray.

What are Profile 3 roofing sheets?

Profile 3 roofing sheets are 3-inch corrugated sheets suitable for small structures, including garages, sheds, and smaller buildings, in agricultural, industrial and domestic sectors, available in 5ft, 8ft, and 10ft lengths.

What are the different types of roof sheets?

Different types of roof sheets include plastic (polycarbonate, acrylic, polystyrene, PVC), metal (steel, zinc), bitumen, polystyrene, and fibre cement.

How thick should a roof profile sheet be?

The roof profile sheet should be 0.5mm or 0.7mm for corrugated sheets, box profile sheets, and flat sheets, while the tile form roofing sheets should be 0.6mm thick.

What are the advantages and disadvantages of various roofing sheet profiles?

Advantages and disadvantages of various roofing sheet profiles include diverse aesthetics, costs, material properties, and installation complexities.

How do I choose the appropriate roofing sheet profile for my building project?

To choose the appropriate roofing sheet profile for your building project, consider factors such as material, climate, and the architectural style of the building.

What are the factors to consider when selecting the proper thickness for roof profile sheets?

When selecting the proper thickness for roof profile sheets, consider factors such as the type of material, load capacity, climatic conditions, and the roof’s span and pitch.