Last updated on

Discover the crucial role and unique challenges of a roof valley because proper knowledge and maintenance can save you from costly repairs in the future.

Key takeaways:

- Closed Valley Roof: Shingles cover valley for a seamless appearance.

- Open Valley Roof: Metal liner channels water off the roof.

- Importance of Roof Valley Flashing: Prevents water infiltration and protects roof structure.

- Choosing the Right Type of Valley: Consider climate, aesthetics, and budget.

- Common Problems in Roof Valleys: Debris accumulation, ice dams, corrosion, improper sealing, shingle misalignment.

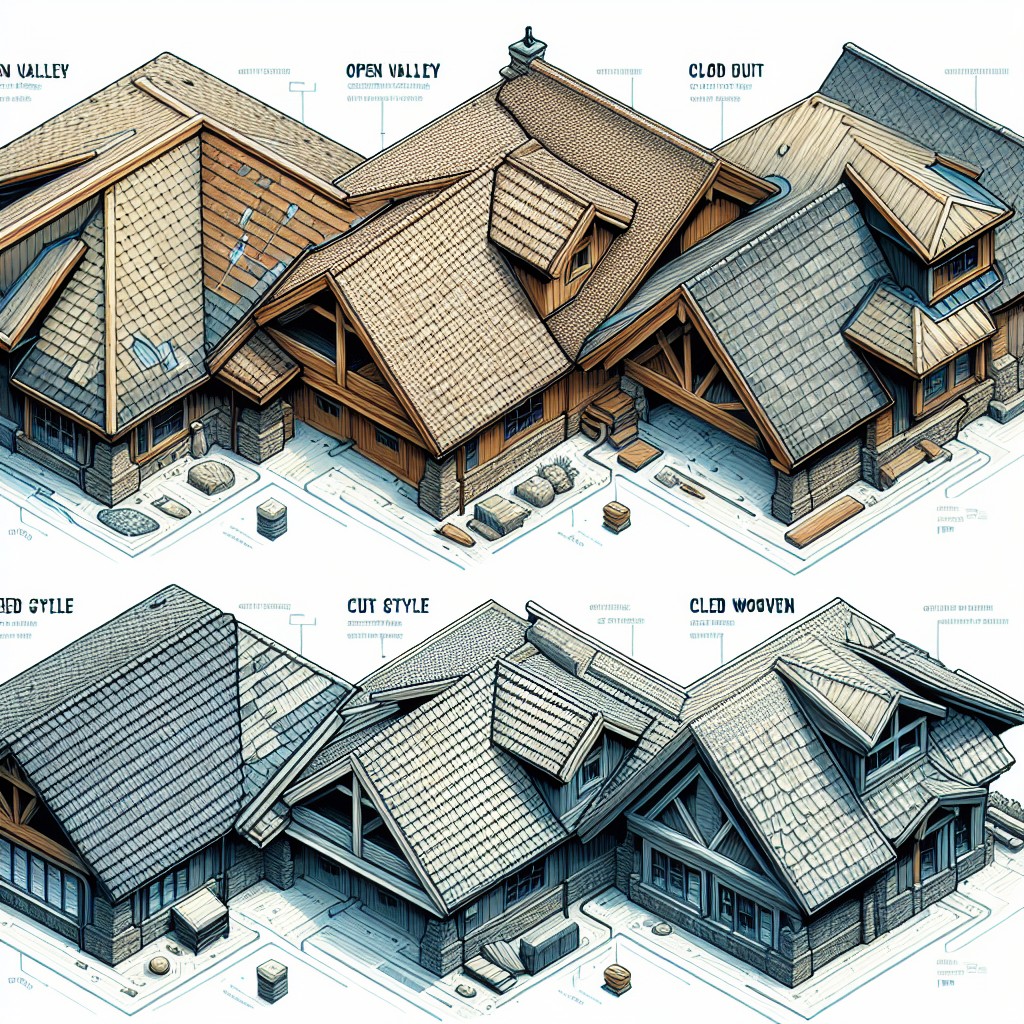

Types of Roof Valleys

When selecting a roof valley design, you have two primary options:

1. Closed Valley Roof: In this design, shingles or roofing material cover the valley entirely. A layer of ice and water shield is applied first, directly onto the decking, with the shingles laid over top. The shingles intersect from both sides of the slope, creating a continuous, sealed surface. This style is commonly admired for its streamlined appearance and is typically more resistant to debris accumulation.

2. Open Valley Roof: This design features a metal liner, often comprised of copper, aluminum, or steel, which is installed along the valley. Shingles do not cover the metal; instead, they are cut and fitted up to the valley’s edges, leaving the metal exposed. The visible metal channel is designed to quickly channel water off the roof. Open valleys are known for their durability and ease of maintenance, especially in areas where heavy rain or snow is common.

Each type of valley serves to effectively direct water off the roof, but the choice between a closed or open valley may depend on climate, aesthetic preference, and roofing material.

Closed Valley Roof

Characterized by shingles that extend across the valley from one side of the roof to the other, closed valleys offer a seamless appearance. The layers of shingles act as a shield, guiding water down the roof’s slope without exposing any metal flashing. This method also has the advantage of a streamlined look, integrating smoothly with the rest of the roofing material.

When installing a closed valley, roofing professionals must carefully align the shingles for a precise, watertight fit. Overlapping is critical; proper technique ensures that the upper layer of shingles completely covers the lower layer, channeling the water away effectively.

In terms of durability, a closed valley can perform exceptionally well if installed correctly, but it’s essential to use high-quality, compatible materials to prevent premature wear. Feelings of precipitation and debris are part and parcel of a roof’s life, and a closed valley must be designed to handle this without compromising the system’s integrity.

Preventative measures and regular checks are necessary since a closed valley can disguise early signs of damage due to its concealing nature. Spotting issues early in a closed valley is key to preventing extensive damage that could require costly repairs or full replacement.

Open Valley Roof

An open valley construction features a metal liner or flashing along the valley, which provides a channel for water runoff. This type of valley exposes the metal flashing, which can be seen between the shingles or other roofing materials. The design encourages water to flow away more efficiently, reducing the likelihood of water penetration.

Typically, materials like aluminum, copper, or steel are used for the flashing, offering a distinct contrast to the roof material and potentially enhancing the roof’s aesthetic.

Key points to understand about open valleys include:

- Enhanced Durability: With less debris accumulation than closed valleys, open valleys can be more durable and allow for better water flow.

- Visual Appeal: The metal can provide a contrasting detail on the roof, and in cases where copper is used, it will develop a patina over time that can add character to the roof.

- Maintenance Considerations: While they do require maintenance, the nature of the open design means that any issues such as buildup or damage are generally easier to spot and address.

- Cost and Installation: The cost of the metal involved means an open valley can be more expensive initially, but the potential for decreased repair costs over time can balance the investment.

When considering an open valley for a roof, it’s vital to ensure that it complements the roof’s overall design and the building’s environmental conditions. A professional roofer can provide advice on optimal materials and methods for installation.

Why Is Roof Valley Flashing Important?

Roof valley flashing serves as a critical line of defense against water infiltration at points where two roof planes intersect. Without proper flashing, these vulnerable junctions are prone to leaks as rainwater naturally congregates in the valleys before draining off the roof.

Flashing channels water away from the felt underlayment and directly into the gutters, significantly reducing the risk of moisture damage to the roof structure. Additionally, flashing is typically composed of durable materials such as metal, which resist corrosion and can withstand severe weather conditions, thus offering prolonged protection for the roof and the overall integrity of the home’s structure.

Regular inspection and maintenance of valley flashing are essential for ensuring the effectiveness of this safeguard and preventing costly water damage repairs.

Choosing the Right Type of Valley for Your Roof

Selecting an appropriate valley style hinges on several factors, including climate, roof design, aesthetics, and budget:

- For regions with heavy snowfall or rain, open valleys may offer better debris clearance and water runoff, preventing buildup and potential leaks.

- Architectural considerations will also guide the choice; certain roof designs may necessitate a particular valley type to ensure structural integrity and water resistance.

- Aesthetically, closed valleys provide a smooth, clean roofline, whereas open valleys might be more visible but allow for the use of materials like metal flashing, which can add a contrasting design element.

- Budget-wise, closed valleys typically use less material and may be incorporated into the shingle installation process, potentially lowering costs, whereas open valleys require additional material, such as metal flashing, which may increase expenses but offer longer-lasting protection.

- It’s crucial to consult with a roofing professional who can assess the specific needs of your roof and provide an informed recommendation that balances functionality with the overall vision for your home’s exterior.

Common Problems in Roof Valleys and Solutions

Debris Accumulation: Leaves, branches, and foreign objects often gather in valleys, impeding water flow and causing leaks. Regular cleaning ensures unobstructed drainage.

Ice Dams: In cold weather, ice can form and prevent water from flowing freely, leading to water backup under the shingles. Proper attic insulation and roof ventilation are critical solutions to this problem.

Corrosion and Wear: The valley area is prone to faster wear due to constant water flow, which can lead to rust on metal materials. Using corrosion-resistant flashing materials and ensuring they are securely fastened can mitigate this.

Improper Sealing: If valley flashing is not sealed correctly, water can seep through. Using a high-quality sealant and ensuring overlapping shingles are well-sealed helps prevent leaks.

Shingle Misalignment: Misplaced shingles near valleys can disrupt water flow and cause leaks. Professional installation and periodic inspections can catch and correct these issues.

Pooling Water: When water pools in valleys, it indicates improper sloping. Reconstructing the valley to create an appropriate slope for water runoff is the corrective measure.

All these issues can be addressed with routine inspection and timely intervention, prolonging the integrity and functionality of the roof valley significantly.

Maintaining Your Roof Valley

Regular maintenance of your roof valley can prevent leaks and extend the lifespan of your roof. Here are some practical steps to keep your valley in good condition:

1. Debris Removal: Keep the valley clear of leaves, twigs, and other debris that can impede water flow and cause blockages. This should be done at least twice a year, preferably in the fall and spring.

2. Gutter Cleaning: Make sure gutters and downspouts are clear, as clogs can cause water to back up into the valley area.

3. Sealant and Flashing Checks: Inspect for any signs of wear or damage to the sealant and flashing. This includes looking for cracks, peeling, or gaps that may allow water ingress.

4. Moss and Algae Treatment: If you notice moss or algae build-up, gently remove it and consider using zinc or lead control strips that inhibit growth.

5. Prompt Repair: Address any issues, no matter how minor, immediately. Small problems can quickly escalate into more significant, costly damage.

6. Professional Inspections: Have a roofing professional conduct an inspection periodically. They can identify and remedy any subtle signs of wear or potential issues that might be overlooked by the untrained eye.

Importance of Regular Maintenance for Roof Valleys

Regular maintenance is crucial to ensuring the longevity and proper function of roof valleys. Debris such as leaves, twigs, and dirt can accumulate, impeding water flow and leading to blockages. When water is unable to pass freely through the valley, it can overflow and seep beneath roofing materials, potentially causing leaks and water damage.

To prevent these issues:

- Inspect the valleys of your roof bi-annually. Look for signs of wear and tear, such as cracked, bent, or corroded flashing.

- Clear away any debris that has gathered to promote unobstructed water flow. This simple task reduces the risk of ice damming in colder climates, where water trapped by debris can freeze and expand.

- Check for loose or damaged shingles around the valley area, which can become entry points for water.

- Ensure that sealants have not deteriorated over time—a common issue that can lead to leaks if not addressed promptly.

By adhering to these points, you will extend the life of your roof valleys and prevent costly repairs. Regular attention is the key to roof resilience, especially in the areas where water is channeled.

Proper Installation Techniques for Valley Flashing

Ensuring the longevity and effectiveness of a roof valley depends greatly on the quality of installation. Below are key points to consider during the installation of valley flashing:

1. Material Selection: Choose flashing material compatible with the roofing material and suitable for the local climate. Common materials include aluminum, copper, galvanized steel, and lead.

2. Surface Preparation: The deck should be clean, dry, and free of debris. Any damage to the roof deck must be repaired before proceeding.

3. Underlayment First: Install an ice and water shield or asphalt-saturated felt as underlayment into the valley for an added layer of protection.

4. Securing Flashing: Flashing should be nailed only at the edges, avoiding penetration in the center of the valley where water flows, to prevent leaks.

5. Proper Lapping: When installing multiple pieces of flashing, ensure proper lapping—typically at least 6 inches—to prevent water infiltration between joints.

6. Sealing Joints: Use a high-quality sealant where flashing connects to roofing material and at any joints to ensure a watertight seal.

7. Shingle Integration: For open valleys, shingle cuts should be straight and clean, and for closed valleys, they must overlap the valley centerline by at least 2 inches.

8. Avoiding Traffic: Minimize foot traffic on the completed valleys, as this can damage the flashing and compromise its integrity.

By adhering to these points, you can ensure that the flashing provides the necessary protection for your roof valley, diverting water efficiently and minimizing the risk of leaks.

Professional Roof Valley Inspection and Repair Services

Entrusting your roof valley repair and inspection to professionals ensures expertise is applied to one of the most vulnerable parts of your roof. Experienced roofers are equipped to detect and address issues, from wear and tear to improper installation, that might not be obvious to the untrained eye.

- Skilled Inspection: A roofing professional will conduct a thorough examination to uncover any signs of damage, such as cracks, rust, or misalignment, which are critical to repair promptly to prevent leaks.

- Quality Repairs: Experts use high-grade materials and proven techniques to repair or replace damaged valley flashings and shingles, ensuring longevity and durability.

- Preventative Measures: During the service, roofers can identify areas prone to future problems and suggest preventative solutions to mitigate potential damage.

- Warranty and Guarantee: Professional services often come with a warranty for the work performed, providing peace of mind that the repair is protected.

By relying on professionals, you are not only securing the functionality of your roof valley but also investing in the overall well-being of your home’s roofing system.

FAQ

What is a valley in a roof?

A valley in a roof refers to the region where two sections of roofing material slope and meet, forming an interior angle primarily designed to enable efficient water flow.

What is the best material for a roof valley?

The best material for a roof valley is metal due to its superior drainage capabilities, allowing for easy flow of rain, snow, leaves, and ice off the roof.

Do roof valleys need flashing?

Yes, roof valleys do require flashing, as it adds to the robustness and longevity of the roof.

How long do roof valleys last?

Roof valleys, under optimum circumstances, can last up to 20 years, but factors such as accumulation of wet leaves can cause corrosion and reduce their lifespan.

How often should roof valleys be replaced?

Roof valleys should typically be replaced every 15 to 20 years, depending on the roof’s overall condition and the local climate.

What are the common problems in roof valleys that homeowners should be aware of?

Common problems in roof valleys typically include leaks, shingle damage, debris buildup, ice dams, and improper installation.

Can you repair a roof valley without professional help and what are the potential risks?

While it is possible to repair a roof valley without professional help, the task involves several potential risks such as falling, incorrect installation leading to water leaks, and possible invalidation of any warranties.