Last updated on

Dive into the reasons why metal roof waterproofing is a crucial aspect of home maintenance because neglecting it can cause unnecessary and expensive damages.

Key takeaways:

- Metal roof types: standing seam, corrugated panels, metal shingles.

- Materials for waterproofing: elastomeric coatings, acrylic, silicone, urethane, rubberized asphalt, bituminous coating.

- How to repair and waterproof a metal roof properly: clean, seal seams and edges, follow manufacturer’s instructions.

- Methods for waterproofing metal roof seams: sealant tape, liquid coatings, standing seam treatment, fastener gaskets.

- Factors affecting the cost of metal roof waterproofing installation: material selection, scope of repairs, labor, geographic location, warranty.

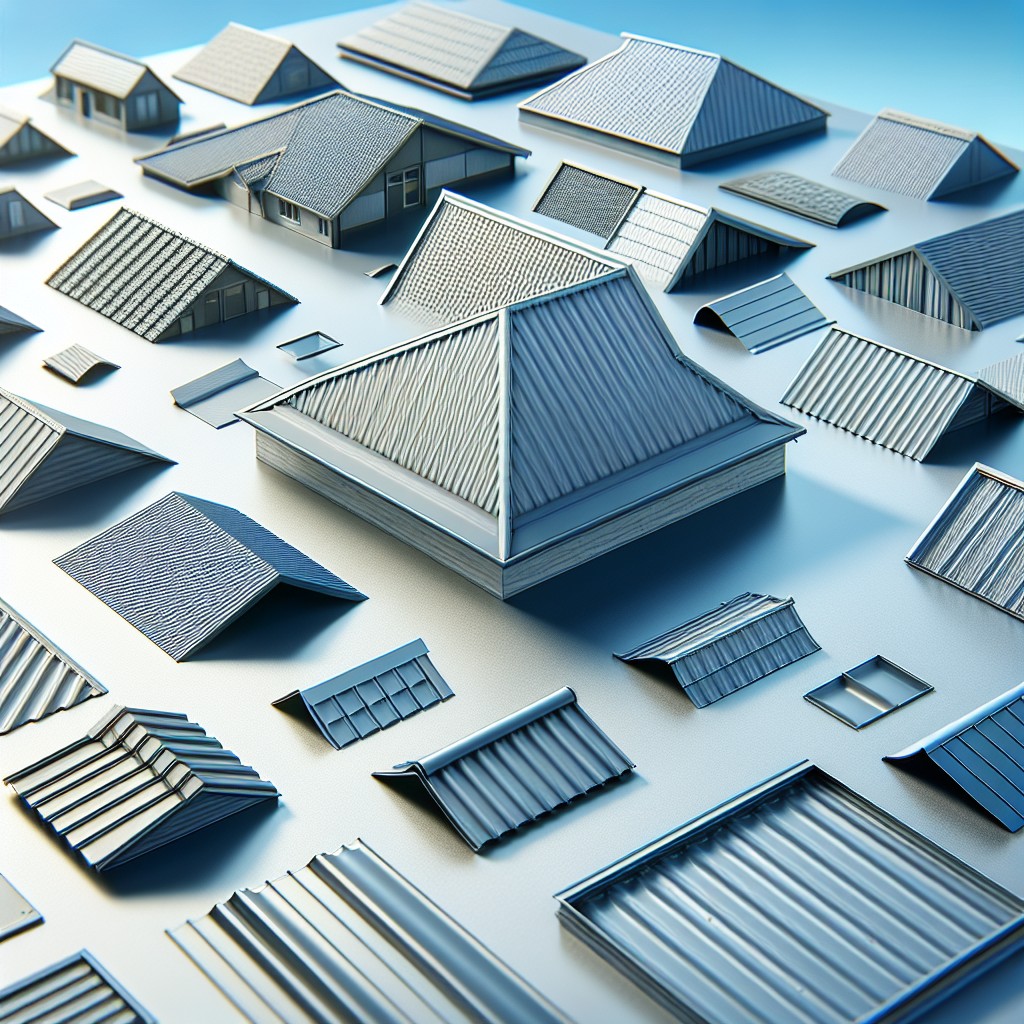

Types of Metal Roofs

Standing seam, corrugated panels, and metal shingles are common residential and commercial options in metal roofing. Standing seam roofs feature raised interlocking seams connecting the panels, offering enhanced durability and a modern look.

Corrugated metal roofs, known for their wave-like pattern, are praised for their strength and quick installation process. Metal shingle roofing mimics traditional asphalt or wood in appearance, but boasts the resilience and longevity inherent to metal materials.

Each type poses unique installation and waterproofing challenges, requiring specific techniques to ensure a watertight finish. Compatibility with the chosen waterproofing method depends on the roof type and should be considered when selecting sealing solutions.

Materials for Waterproofing Over Metal Roofs

Selecting the appropriate waterproofing material is crucial for ensuring the longevity of a metal roof. Elastomeric coatings are popular due to their flexibility and ability to expand and contract with the metal’s movement. Acrylic and silicone coatings are amongst the most sought after, with silicone providing exceptional resistance to weathering and UV rays, while acrylic is favored for its cost-effectiveness and ease of application.

For those seeking a more durable solution, urethane coatings offer robust protection against heavy foot traffic and abrasive conditions. Polyurea-based materials, known for rapid curing times, create a seamless barrier that can withstand a wide array of environmental factors.

Rubberized asphalt, a self-adhering membrane that can be applied to the metal surface, excels in preventing water infiltration on lower-sloped roofs. It’s noteworthy for its self-sealing properties around fasteners and exceptional adherence to the underlying metal.

To combat rust and corrosion, a layer of bituminous coating might be applied before the waterproofing process, especially in environments where moisture and salty air are prevalent.

Choosing between these options requires consideration of the specific climate conditions, roof profile, and longevity desired. It is essential to adequately prepare the metal surface before application, ensuring it is clean, dry, and structurally sound to receive the chosen material.

How to Make a Repair and Waterproof a Metal Roof Properly

Effectively repairing and waterproofing a metal roof hinges on meticulous preparation and application. Begin by cleaning the area to remove dirt, debris, and rust, ensuring the surface is dry and smooth.

For small punctures or gaps, apply an appropriate sealant or use patching tape specifically designed for metal roofs. Larger damaged sections may require cutting out and replacing with new metal panels.

Focus on the seams and edges, as these are common leak points. Use seam tape followed by a high-quality metal roof coating for a watertight seal. When applying the coating, use uniform strokes and ensure complete coverage, particularly around fasteners and roof fixtures.

It’s imperative to follow the manufacturer’s instructions regarding coating thickness and curing time. Regular inspections aid in early detection of potential issues, allowing for prompt maintenance and prolonging the roof’s integrity.

Waterproofing of Metal Roof Seams

Ensuring that seams are properly sealed is crucial in the waterproofing of metal roofs, as seams are the most common entry points for water. Here are several methods used to address this critical area:

- Sealant Tape: A quick and effective option for sealing seams is the use of butyl or acrylic sealant tape. It is applied directly over the seams, creating a watertight barrier.

- Liquid Coatings: These are applied over the entire roof surface, filling in the seams and any slight gaps. The coatings cure to form a seamless, waterproof membrane.

- Standing Seam Treatment: Special tools are used to crimp and seal the raised seams of standing seam metal roofs, removing the need for additional sealants.

- Fastener Gaskets: For roofs with exposed fasteners, ensuring each fastener is topped with a durable rubber gasket can prevent water intrusion at the seams.

Proper application and regular inspection of seam treatments are vital for long-lasting waterproofing protection. Always adhere to the manufacturer’s guidelines for the best results.

The Cost of a Metal Roof Waterproofing Installation

The investment required for waterproofing a metal roof can fluctuate depending on several key factors. On average, homeowners can anticipate costs ranging from $1,500 to $7,000, which translates to about $1 to $5 per square foot, but these figures can vary widely based on roof size, complexity, and the specific waterproofing product chosen.

When considering a waterproofing project, the following elements primarily influence the overall cost:

- Material Selection: Higher quality coatings, such as silicone or polyurethane, might have a steeper initial cost but offer extended durability and may reduce long-term expenses due to fewer reapplications.

- Scope of Repairs: Should there be a necessity for preliminary repairs to the substrate or replacement of damaged panels, costs will increase accordingly.

- Labor: Professional installation typically ensures the job is done correctly; however, it will add to the project’s cost versus a do-it-yourself approach.

- Geographic Location: Labor and material costs can differ significantly based on regional market rates, affecting the final price.

- Warranty: Opting for a product with a robust warranty may come with a higher price tag but can provide peace of mind and potential savings on future repairs.

To ensure cost-effectiveness, it is advisable to obtain multiple quotes from reputable contractors and compare the services, materials offered, and warranties included. Effective waterproofing not only protects the roof but also adds to the lifespan of the structure, making it a prudent investment.

Choosing the Right Waterproofing Material

Selecting an appropriate waterproofing material is critical for the longevity and performance of a metal roof. Factors to consider include:

- Metal Type: Compatibility with the specific metal of your roof, whether it’s aluminum, steel, copper, or another alloy, is crucial to prevent corrosive reactions.

- Climate: Materials should be chosen based on local weather conditions. In areas with extreme temperatures, a material that can expand and contract without breaking is vital.

- Environmental Considerations: For environmentally conscious choices, look for low-VOC, eco-friendly options that deliver durability without harmful chemicals.

- Durability: High-quality materials resist cracking, peeling, and erosion, which is essential for long-term protection and reduced maintenance.

- Energy Efficiency: Reflective coatings can help in reducing cooling costs by deflecting UV rays and reducing heat absorption.

- Manufacturer Reputation: Opt for materials from reputable manufacturers that offer warranties and have positive reviews for performance and longevity.

Choosing wisely among the various sealants, membranes, and coatings available will pay off with a metal roof that remains watertight and in excellent condition for years to come.

Installation Process

Before proceeding with the installation, ensure the metal roof is clean, rust-free, and dry. Remove any debris, dust, or old coatings that could prevent adhesion. Apply a rust-inhibiting primer if necessary, particularly on older roofs that have experienced corrosion.

Choose a calm, dry day for the application. Most sealants require a specific temperature range for optimal curing—typically above 50°F. Apply the waterproofing sealant or coating using a roller, brush, or sprayer, starting from the roof’s peak and working downwards to prevent stepping on wet surfaces.

Address the seams and edges first as they are the most vulnerable points for water ingress. A thorough application here is crucial for preventing leaks. For the main roof area, apply the coating evenly, following the manufacturer’s recommended coverage rates to ensure maximum protection.

Overlap each pass to ensure full coverage, and avoid thin spots which could compromise the waterproofing integrity. Allow the first coat to dry completely according to the product specifications before applying a second coat, if required, to achieve adequate thickness and durability.

Regularly check the weather forecast to avoid rain or heavy dew during the curing period, which can affect the performance of the waterproofing layer. After installation, inspect the roof periodically and touch up any areas where the coating shows signs of wear or damage to maintain its waterproof integrity.

Metal Roof Coating Coverage

Understanding the coverage capacity of metal roof coatings is crucial for efficient application and budgeting. Coverage rates are typically measured in square feet per gallon. To calculate the amount needed, one must determine the total area of the roof in square feet and divide it by the spread rate of the chosen coating. It’s important to note that the spread rate can vary depending on the manufacturer and the product type.

For instance, acrylic elastomeric coatings may cover approximately 100 square feet per gallon on a smooth surface. Rougher surfaces will require more material to achieve the same level of protection. Additionally, the number of coats recommended by the manufacturer will impact the total volume of coating needed. Two coats are common, effectively halving the area covered per gallon.

Keep in mind that while a thicker coating may improve longevity and performance, it can also affect the total coverage. Always follow manufacturer guidelines for optimal thickness and ensure to include extra material for touch-ups and potential waste.

Metal Roof Coating Features

When selecting a coating for a metal roof, several features are paramount for efficient waterproofing:

- Elasticity: Look for products with high elasticity. This allows the coating to expand and contract with temperature changes without cracking.

- UV Resistance: UV-resistant coatings help prevent degradation from the sun, ensuring longevity.

- Corrosion Inhibition: A coating should provide a protective barrier against rust and corrosion, particularly important for metal roofs in coastal areas or places with high pollution.

- Energy Efficiency: Reflective coatings can reduce cooling costs by reflecting sunlight, thereby keeping buildings cooler.

- Adhesion: The coating must adhere strongly to the metal surface to provide a seamless waterproof barrier.

- Ease of Application: Some coatings can be applied with simple tools like brushes or rollers, which make the installation process smoother and less time-consuming.

Considering these features ensures the selected coating not only waterproofs the metal roof but also contributes to its durability and functionality.

Maintenance Tips

Regular inspections of your metal roof are crucial to detect any signs of wear and tear, such as scratches, corrosion, or seam separations, which could compromise waterproofing. Conduct these inspections biannually or after severe weather events.

Keep the roof surface clean of debris, such as fallen leaves and branches, as accumulated material can hold moisture and lead to corrosion. A soft brush or washing with water can often suffice for cleaning away debris.

Trim overhanging tree branches to prevent them from scratching the metal surface or shedding leaves and twigs onto the roof, which can damage the waterproofing coating over time.

Check for and promptly repair any minor damages to the roof’s coating or sealant to prevent water infiltration. Use touch-up paint designed for metal roofs on scratches, and sealant compatible with your roof’s material for small gaps or holes.

Ensure your gutters and downspouts are clear of obstructions to allow for proper water runoff. Clogged gutters can cause water to pool on your roof, which may lead to leaks and rust formation.

Monitor the seals around flashings, vents, and skylights, as these roof features are common spots for leaks. Replace sealing compounds as needed to keep these areas watertight.

Consider professional assessments periodically. A roofing specialist can help you identify potential issues that may not be obvious to the untrained eye and provide expert maintenance advice or services.

FAQ

Can you waterproof a metal roof?

Yes, a metal roof can indeed be waterproofed using various methods, such as applying a Liquid Rubber Waterproof Sealant.

How do you weatherproof a metal roof?

Weatherproofing a metal roof can be effectively achieved through the application of Elastometal waterproofing paint using an airless spray, ensuring a dry film thickness of approximately 175 microns per coat.

What is the best way to stop a metal roof from leaking?

The optimal method to halt leaks in a metal roof is by installing sealant or butyl tape between the overlapping metal panels.

What materials are typically used for waterproofing a metal roof?

Typically, materials such as elastomeric coatings, metal roof sealants, and rubberized asphalt are used for waterproofing a metal roof.

What are the common waterproofing techniques for metal roofs?

The common waterproofing techniques for metal roofs include the use of waterproof coatings, seam tape, rubberized asphalt, butyl tape, and thermoplastic coverings.

How frequently should a metal roof be inspected for potential water damage?

A metal roof should be inspected for potential water damage at least twice a year, typically during the spring and fall.