Last updated on

Diving into the importance of selecting the right minimum pitch for a metal roof, this article is vital because the correct slope not only enhances the durability of your roof but also optimally channels rainwater and debris.

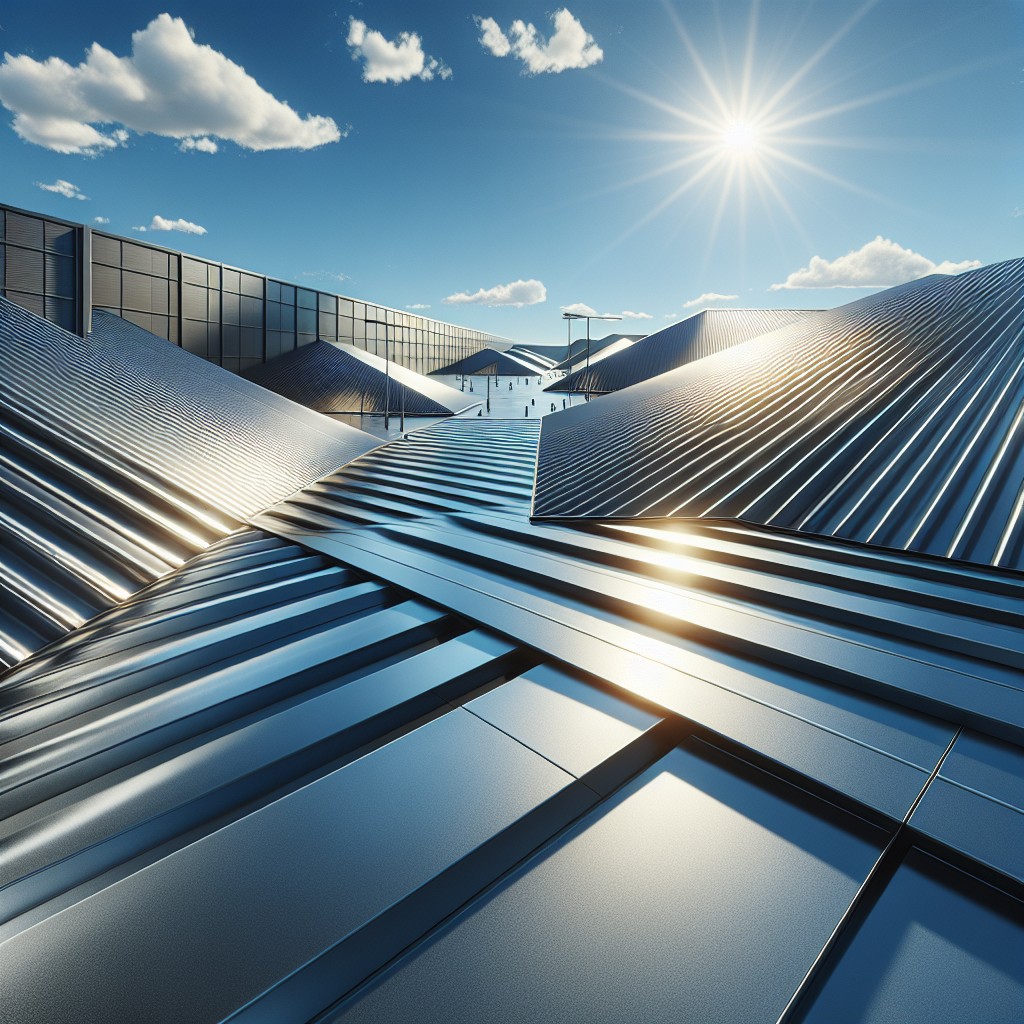

Selecting the correct pitch for a metal roof is crucial to safeguard your home from the elements. A roof’s slope not only dictates how effectively water and snow are shed but it also impacts the overall design of your house. Different metal roofing systems – from the sleek lines of standing seam to the traditional profiles of metal shingles and the rugged feel of corrugated panels – each come with their own set of recommended minimum slope requirements to ensure peak performance.

In this article, you’ll gain a comprehensive understanding of how to determine the optimal pitch for various types of metal roofs, helping you to make an informed decision that balances functionality with aesthetics.

Key takeaways:

- Proper slope ensures water drainage, preventing leaks and structural damage.

- Roof pitch affects water runoff, snow load, and aesthetic.

- Different metal roofing systems have varying minimum slope requirements.

- Standing seam roofs require a minimum slope of 1:12 for optimal performance.

- Metal shingles, tiles, and corrugated roofs have different minimum slope requirements.

Minimum Roof Pitch for Metal Roofs

The pitch of a roof is its steepness, quantified as the ratio of the vertical rise to the horizontal run, represented as inches per foot. A metal roof requires a certain minimum pitch to ensure proper water runoff. Failure to adhere to the recommended slope can lead to water infiltration, increased snow load retention, and potential structural damage.

To measure pitch, one would take a level and a tape measure; on a level 12-inch horizontal line (the run), measure the vertical height (the rise) the roof climbs. For example, a 4-in-12 slope means the roof rises 4 inches for every 12 inches of horizontal run.

Understanding the pitch is crucial for selecting the appropriate metal roofing system and ensuring longevity and performance.

Understanding Roof Slope

Roof slope, or pitch, is the angle at which a roof rises over a 12-inch horizontal distance. Here are key points to understand:

- Pitch is usually expressed with a ratio, such as 4:12, which means the roof rises 4 inches for every 12 inches of horizontal span.

- A steeper pitch means more vertical rise, and flat roofs are close to a 0:12 ratio.

- The slope affects water runoff, snow load capacity, and the aesthetic of the house.

- It determines the type of roofing materials that can be used, as some require a minimum slope.

Importance of Slope for Metal Roofs

Adequate slope on metal roofs is critical for effective water runoff. The angle prevents water from pooling, which mitigates the risk of leaks and structural damage.

Additionally, properly sloped metal roofs allow for efficient snow and debris shedding, maintaining the roof’s integrity and elongating its lifespan.

Moreover, slope influences the aesthetic appeal of the roof and can impact the building’s overall design. It’s important to find the balance between architectural design desires and functional requirements when considering slope for metal roofing.

Common Roof Slopes

Roof slopes are typically measured in terms of rise over run, expressing how many inches the roof rises for every 12 inches of horizontal distance. Here is a straightforward breakdown of common roof pitches:

– Low slope: Ranges from 1/4:12 to 3:12. These are often found in commercial buildings and require special materials to ensure water doesn’t pool on the roof. – Conventional slope: Often seen in residential construction, slopes in this category range from 4:12 to 9:12 and are suitable for a variety of roofing materials. – Steep slope: This category includes pitches that are 10:12 and higher, providing a classic A-frame look that is particularly efficient in snow and rain runoff.Each pitch category has implications for material selection, durability, and architectural style. It’s crucial to choose a slope aligned with the climate in your region and the aesthetic goals for your building.

Minimum Slope Requirements for Different Metal Roof Systems

Slope requirements vary significantly across metal roofing systems. Optimal functionality and longevity hinge largely on adhering to these standards, which differ based on the roof’s profile and application methods.

For standing seam systems, a minimum slope of 1/4:12 is generally recommended, allowing for efficient water runoff without compromising the integrity of the seam. It’s notable that some manufacturers have enhanced seaming techniques that may even lower this requirement in certain scenarios.

Corrugated panels often need a slope of at least 3:12 to ensure proper drainage. Moreover, the corrugation design itself helps guide water and snow off the roof, reducing the risk of accumulation and potential damage.

Metal shingles, imitating the look of traditional shingle materials, generally require a minimum slope of 3:12. This specification ensures that they perform effectively, avoiding water infiltration that can occur at flatter angles.

Similarly, metal tiles must be installed on a slope not less than 2.5:12 to prevent water from permeating the roof’s surface, especially at the overlap points which can be vulnerable if not properly angled.

Considering these slope requirements is crucial during the planning stages of a metal roof installation to guarantee a durable and weather-resistant roofing solution.

Standing Seam Metal Roof Minimum Slope

Standing seam metal roofs, renowned for their durability and modern appearance, require an adequate slope to ensure optimal performance. The industry standard minimum slope for a standing seam system is 1:12. This equates to one inch of vertical rise for every twelve inches of horizontal run.

Key Points:

- The 1:12 ratio prevents water accumulation, promoting efficient drainage and reducing the risk of leakage.

- A steeper slope may be preferable in regions with heavy snowfall or intense rain for augmented water or snow shedding capacity.

- Low-slope applications necessitate precise installation techniques and may involve additional underlayment materials to safeguard against water infiltration.

- Adherence to this minimum slope is critical to capitalize on the inherent weather resistance of standing seam metal roofing systems.

By following these guidelines, a standing seam metal roof can provide a reliable, long-term roofing solution.

Corrugated Metal Roof Minimum Slope

For corrugated metal roofing systems, the accepted minimum pitch is 5 degrees or a 1:12 slope. This specification ensures adequate water runoff to prevent leaks, pooling, and potential corrosion.

Always adhere to manufacturer guidelines as some may vary slightly with their recommendations, often depending on the corrugation profile and climate considerations.

It’s also essential to factor in proper underlayment and careful installation to achieve a durable and weather-tight roof at the minimum slope.

Metal Shingles Minimum Slope

Metal shingles are often selected for their aesthetic appeal and durability. When installing these, it’s crucial to adhere to the manufacturer’s specified minimum roof pitch to ensure proper water drainage and prevent leaks. Typically, metal shingles require a pitch of at least 3:12. This means for every 12 inches of horizontal distance across the roof, it should rise by at least three inches.

However, some advanced interlocking metal shingle systems can be used on slopes as low as 2:12. To guarantee optimal performance, it is essential to check the product specifications and consult with the manufacturer if attempting to install on lower slopes.

Proper underlayment is also critical for metal shingle roofs, as it provides an additional layer of moisture protection. For lower-sloped roofs, a high-quality, waterproof underlayment is the best practice to enhance the roof’s integrity and longevity.

Metal Tiles Minimum Slope

Metal tiles, designed to emulate traditional clay, concrete, or slate tiles, typically require a roof slope of at least 3:12. This translates to 3 inches of rise for every 12 inches of run. The steeper pitch facilitates proper water runoff, crucial for preventing leaks and ensuring the longevity of the roofing system.

When installed on pitches less than 3:12, special underlayments are necessary to maintain the integrity of the metal tile roof. Additionally, increased attention must be given to the overlap and sealing of the tiles to bolster water resistance.

It’s important to note that while metal tiles can be used on a variety of slopes, they excel aesthetically and functionally on higher pitches. On steeper roofs, metal tiles provide an elegant appearance with the added benefit of durable, lightweight protection.

Criteria for Selecting Metal Roof Slope

Selecting the appropriate slope for a metal roof involves evaluating several factors to ensure longevity and effectiveness. Here are key considerations:

- Climate Conditions: In regions with heavy snowfall or intense rain, a steeper pitch can help in snow and water runoff, preventing accumulation that could lead to structural damage or leaks.

- Aesthetic Preference: The pitch can substantially impact the appearance of a home. Some styles may benefit from a steeper roof, while modern designs might favor lower slopes.

- Building Codes: Local building codes can dictate minimum pitch requirements to align with regional weather patterns and construction standards.

- Material Compatibility: Certain metal roofing materials perform better at specific pitches. For instance, standing seam systems are well-suited for steeper slopes, while metal tiles can be appropriate for more moderate slopes.

By carefully weighing these criteria, homeowners can make informed decisions that balance functionality and design, ensuring a metal roof that is both durable and aesthetically pleasing.

FAQ

Is a 2 12 roof pitch OK for metal roof?

A 2:12 roof pitch can support a metal roof, provided the correct metal roofing panel profile is used.

What is the minimum slope for a corrugated roof?

The minimum slope for a corrugated metal roof is 1/2:12.

Is a 4 12 roof pitch good?

Yes, a 4/12 roof pitch is good, typically falling in the middle category between low pitch and steep pitch roofs.

What is the lowest allowable roof pitch?

The lowest allowable roof pitch is 1/4:12, equating to a 1/4 inch rise for every 12 inches of run.

How does roof pitch affect the performance of a metal roof?

Roof pitch significantly affects the performance of a metal roof as it can influence water runoff, snow load capacity, and even the overall aesthetic appeal.

Can low-pitched roofs benefit from a standing seam metal system?

Yes, low-pitched roofs can benefit from a standing seam metal system as it provides effective waterproofing and longevity, even on pitches as low as 1/4:12.

What are some common issues associated with a low slope metal roof?

Common issues associated with a low slope metal roof include improper installation, lack of maintenance, and pooling water.