Last updated on

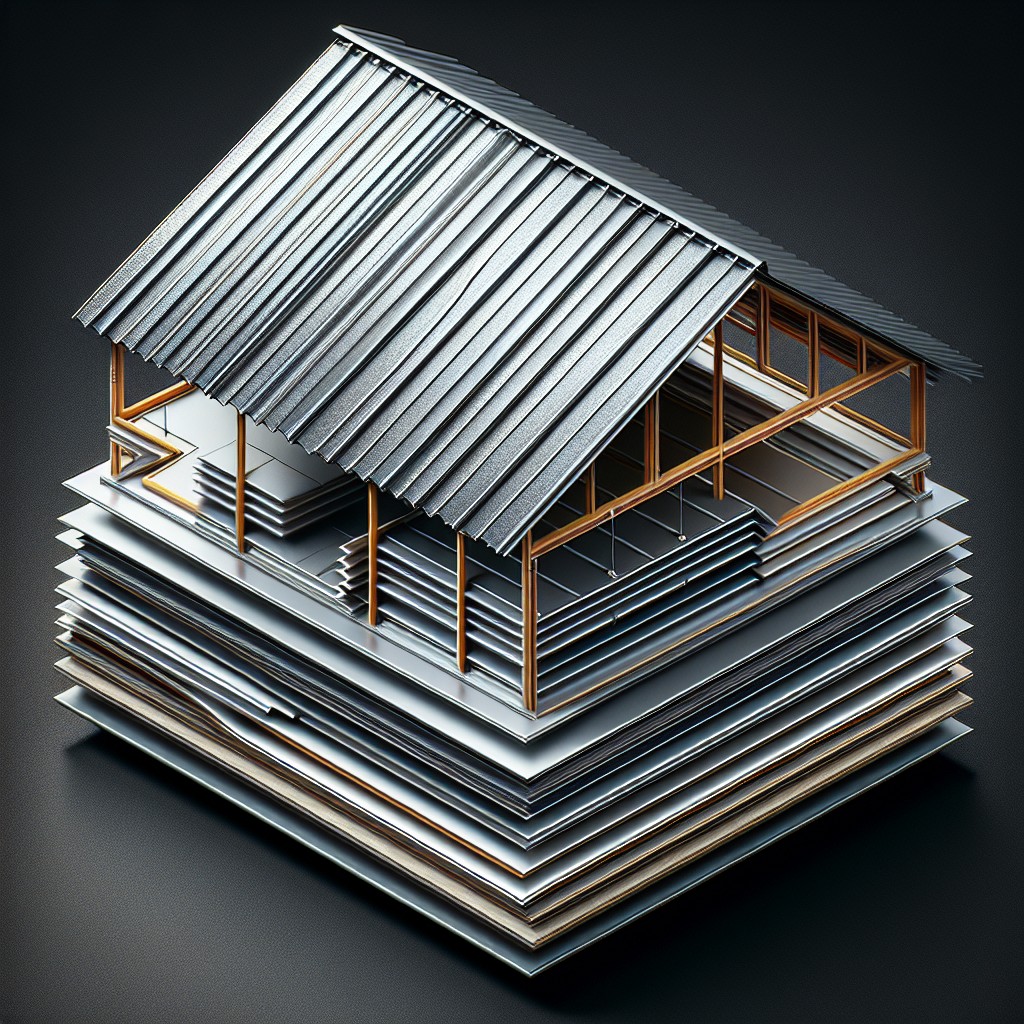

Because selecting the right underlayment for metal roofing can sharply increase its performance and lifespan, this article presents a comprehensive guide to making the most optimal choice.

Key takeaways:

- Underlayment protects against moisture and provides weather resistance.

- Metal roofs need underlayment for moisture barrier and better performance.

- Felt, synthetic, and self-adhering membrane are common underlayment materials.

- Consider climate, roof design, and budget when choosing underlayment.

- Proper installation and adherence to building codes is crucial for underlayment.

What Is Roof Underlayment?

Roof underlayment is a critical barrier, serving as a protective layer between the metal roofing and the sheathing of the roof. This layer fulfills multiple functions:

- Moisture Protection: It acts as a secondary defense against water infiltration, ensuring that if moisture gets past the metal panels, it doesn’t reach the roof deck.

- Weather Resistance: The underlayment provides temporary protection against the elements during the installation process and serves as a shield against wind-driven rain or snow that may get beneath the metal roof panels.

- Improved Longevity: By adding an extra layer of protection, underlayment can help extend the lifespan of the roof structure and sheathing by guarding against condensation and potential wood rot.

- Regulatory Compliance: Building codes in many areas require the use of underlayment for metal roofs to meet certain standards for fire resistance and weatherproofing.

Understanding these aspects of underlayment highlights its importance in roofing systems and can guide homeowners and contractors in ensuring their metal roofs are installed with the utmost protection and care.

Does My Metal Roof Need an Underlayment?

Metal roofs are known for their durability and weather resistance, but installing underlayment beneath the metal panels is a critical step for ensuring the roof’s long-term performance. Here’s why:

- Moisture barrier: Underlayment acts as a secondary defense against water infiltration, which can cause damage to the roof deck.

- Vapor protection: It also serves to reduce condensation that can occur on the underside of metal roofing due to temperature differences.

- Uniformity: It provides a smooth surface over the roof deck, which helps to prevent the metal panels from showing imperfections.

- Sound insulation: Adding underlayment can dampen noise from rain, hail, or debris, which can be louder on metal than other roofing materials.

- Longevity: Some metal roofing manufacturers require underlayment for their warranties to be valid, acknowledging the role of underlayment in extending the life of a roof.

Considering these points, underlayment is not just an additional layer; it serves crucial protective and functional roles in a metal roofing system.

Underlayment Materials

Selecting the appropriate underlayment material is a vital step in metal roofing installation and directly affects the durability and performance of your roof. Here are the common underlayment materials used beneath metal roofing:

1. Felt Underlayment: This is also known as tar paper and is made of a fiberglass or polyester fleece soaked in asphalt. It comes in two thicknesses: #15 and #30, with #30 being the more durable option. Felt is water-resistant and provides basic protection at a lower cost.

2. Synthetic Sheet Underlayment: Constructed from polymers and polypropylene or polyethylene, synthetic underlayment is lighter and stronger than felt. It often has a longer life span, is resistant to mold growth, doesn’t absorb water, and can be more resistant to tearing during installation. It comes in larger rolls, which reduces seam numbers and installation time.

3. Self-adhering Membrane Underlayment: This material has a sticky back surface that adheres directly to the roof deck. It is excellent for waterproofing, especially in regions with severe weather conditions like snow and ice dams. It also acts as a barrier against water and ice ingress, which is crucial for lasting roof protection.

Each material has its advantages and installation guidelines that should be considered in relation to your roof’s design and the local climate. Proper selection and installation of underlayment materials are critical for ensuring the roof’s longevity and protecting your home from the elements.

Felt Underlayment (Asphalt Felt/Tar Paper Underlayment)

Felt underlayment, commonly known as tar paper, is a traditional option and has been used for decades due to its reliable performance and cost-effectiveness. It’s available in two thicknesses: 15-pound and 30-pound—the latter providing superior durability and tear resistance.

Composed of a base made from natural materials such as wood cellulose, the felt is then saturated with asphalt to enhance its waterproofing capabilities. While relatively water-resistant, felt underlayment is not waterproof and may absorb moisture over time, which can potentially lead to wrinkling that may affect the metal roof installation.

Its permeability allows for better airflow, which can help the roofing system to manage condensation and ventilation issues, a consideration in climates with high temperature fluctuations.

Installation typically involves rolling out the felt on the roof deck and securing it with staples or cap nails. This underlayment provides a decent grip for walking during installation, although it can become slippery when wet.

For enhanced protection, especially in regions prone to wind-driven rain or ice damming, one may opt for the heavier 30-pound felt or consider a more advanced underlayment technology.

Synthetic Sheet Underlayment

Synthetic sheet underlayment stands as a modern solution for metal roofing systems, offering a range of advantages over its traditional felt counterparts. These sheets are crafted from woven polyethylene or polypropylene, which grants them superior durability and tear resistance. Their lightweight nature makes them easier to install, reducing labor time and costs.

With a high resistance to moisture, synthetic underlayments keep the roof deck dry, preventing leaks and water damage that can otherwise compromise the integrity of the roof structure. Additionally, these sheets are typically more breathable than felt, promoting better air circulation and reducing the potential for mold growth.

Since they are less susceptible to buckling and wrinkling, synthetic sheets provide a smoother surface for the metal panels, which can result in a more aesthetically pleasing finished roof. Moreover, they often come with longer warranty periods, which gives homeowners peace of mind knowing their investment is protected for the long term.

In regard to climate considerations, synthetic materials excel in both hot and cold environments, maintaining their protective properties regardless of temperature fluctuations. This adaptability makes them an excellent choice for a wide range of geographic locations.

Lastly, synthetic underlayments have anti-slip properties which provide a safer surface for installers, an important aspect to consider for those prioritizing the safety of the roofing crew.

Self-adhering Membrane Underlayment

Self-adhering membrane underlayments offer a peel-and-stick application process, providing a strong seal against moisture. They are typically constructed from modified bitumen and feature a sticky backing which adheres to the roof deck creating a waterproof or water-resistant barrier.

Key points:

- Ideal for regions with extreme weather conditions, such as high winds and heavy snowfall, due to their excellent adhesion properties.

- Often used in critical areas like eaves, valleys, and around roof penetrations to prevent ice dams and protect against wind-driven rain.

- Provides superior leak protection by sealing around the fasteners that penetrate through when installing the metal panels.

- More durable and less prone to tearing compared to felt and synthetic underlayments, making them a long-lasting option.

- Their self-sealing nature allows for quick and easy repairs of any accidental punctures during the metal roof installation.

- Reflective options are available and can be chosen to reduce heat absorption, thereby enhancing energy efficiency under metal roofing systems.

Which Underlayment Should You Choose?

Selecting the appropriate underlayment for your metal roof hinges on several factors, including climate, roof design, and budget. In regions with frequent and heavy rainfall or snow, a synthetic sheet underlayment or a self-adhering membrane offers superior waterproofing protection. These are also advisable for roofs with low slopes where water tends to pool. For typical residential applications, a high-quality synthetic underlayment may provide the best balance of durability and cost-effectiveness.

In contrast, felt underlayment, while more affordable, might be suitable in dry climates where moisture is less of a concern. However, it’s essential to note that felt can absorb moisture and is therefore less ideal for very humid climates or coastal areas where salt spray is present.

The longevity of the metal roofing system should also be a consideration. A high-performance underlayment can extend the life of the roof by providing an additional layer of protection against the elements. For optimal energy efficiency, some underlayments offer a reflective surface that can help reduce heat gain in the attic space.

Always adhere to local building codes and manufacturer’s recommendations, as they can dictate specific underlayment requirements for warranty and performance standards. Consulting a roofing professional can provide personalized guidance based on the unique aspects of your roofing project.

Factors To Consider When Choosing Underlayment

Selecting the appropriate underlayment for your metal roof depends on several key considerations:

1. Climate: In areas with frequent rain or snow, a waterproof underlayment is imperative to protect the roof deck from moisture. For hot climates, reflective underlayment that reduces heat absorption may be beneficial.

2. Roof Pitch: Steeper slopes typically require different underlayment than low slope roofs as water runoff characteristics vary.

3. Longevity and Durability: Premium materials such as synthetic underlayments offer enhanced durability and longer lifespans compared to felt options.

4. Compatibility: Ensure the underlayment is compatible with the metal roofing to avoid chemical reactions that can lead to corrosion.

5. Local Building Codes: Adhere to regional regulations which may dictate the type and installation method of underlayment.

6. Budget: While cost should not be the sole determining factor, it is important to consider the balance between quality and expense.

7. Manufacturer’s Recommendations: Follow guidelines provided by the metal roofing manufacturer to maintain the roof’s warranty.

By carefully weighing these factors, you can choose an underlayment that provides the best protection for your metal roof.

Metal Roof Underlayment Requirements & Attachment

Proper installation is crucial for the performance of metal roof underlayment. Adherence to building codes and manufacturer specifications ensures the longevity and effectiveness of the roof system. Here are key aspects to consider during installation:

1. Overlap and Seams: Sheets or rolls of underlayment must overlap by a minimum amount, often a few inches, and be properly sealed to prevent water ingress.

2. Fastening: Use cap nails or staples to secure the underlayment to the decking. The pattern and spacing of fasteners are typically dictated by local building codes and wind uplift requirements.

3. Deck Preparation: The roof deck should be clean, dry and free of any debris or protruding nails that could damage the underlayment before attachment.

4. Valleys and Edges: In these critical areas, it is often required to apply a double layer of underlayment or a specialized self-adhering product to prevent water from pooling and seeping through.

5. Ventilation: Ensure that the installation of underlayment does not obstruct attic ventilation, which is vital for managing condensation and temperature under a metal roof.

6. Roof Penetrations: Around vents, pipes, and chimneys, use additional sealants or boot flashing to reinforce these vulnerable spots against leaks.

By focusing on these elements, the underlayment will adequately support the metal roofing material, contributing to a roof system that stands the test of time and weather.

FAQ

Should I put anything under a metal roof?

Yes, a roof underlayment should be installed under a metal roof as it provides a protective barrier against various weather elements and enhances energy efficiency.

Do I need to put plywood under a metal roof?

Yes, it is necessary to place plywood under a metal roof as it ensures a moisture barrier and a solid, uniformly flat surface that prevents the occurrence of leaks and uneven distribution of the metal panels.

Do I need furring strips under metal roof?

Yes, furring strips are generally recommended under a metal roof for securing the roof and increasing your home’s energy efficiency by minimizing heat transfer.

Can you put metal roof directly on rafters?

Yes, a metal roof can be mounted directly on the rafters due to the lightweight nature of corrugated metal panels that enable them to fit almost any situation.

What are the best underlayment materials for metal roofing?

The best underlayment materials for metal roofing are synthetic, self-adhering underlayment such as rubberized asphalt and non-bitumen synthetic underlayment due to their waterproofing capabilities, durability, and ease of installation.

How does insulation work with metal roofing?

Insulation in metal roofing works by reducing the heat transfer from the metal roof to the building’s interior, aiding in maintaining optimal indoor temperatures.

Is it necessary to install a moisture barrier under a metal roof?

Yes, it is necessary to install a moisture barrier under a metal roof to prevent condensation, which can lead to rusting and leaks.

Related

- How to Build a Roof Over a Deck: Complete Steps for Optimized Outdoor Space

- Metal Roof Insulation: Essential Information and Expert Tips

- Valley Metal Roof: A Comprehensive Guide on Installation and Maintenance

- How to Shingle a Shed: Easy-to-Follow Steps for a Successful Project

- Roof Installation: Step-by-Step Guide to a New Roof